MEBAeco 510 DGA-2300

Product information "MEBAeco 510 DGA-2300"

- The ergonomic panel control can be networked and offers various option packages:

- Setting of sawing programs in the AV

- Import of saw programs from CAD with DSTV interface and data export

- Automatic material feed:

- Available in a compact design for shorter sections or with flexible push-in tongs in almost any length

- Exact positioning of the material using servo positioning technology

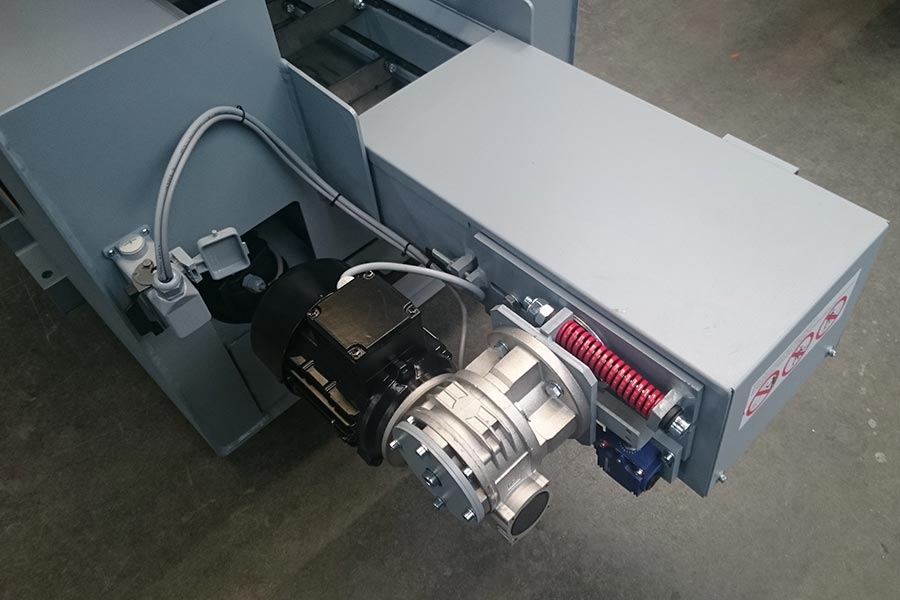

- Pioneering electric saw feed with ball screw

- highest cutting performance and quality, while being gentle on the saw blade

- Consistent use of the most modern recirculating ball guides

- smooth-running, highly resilient, low-maintenance and free of play

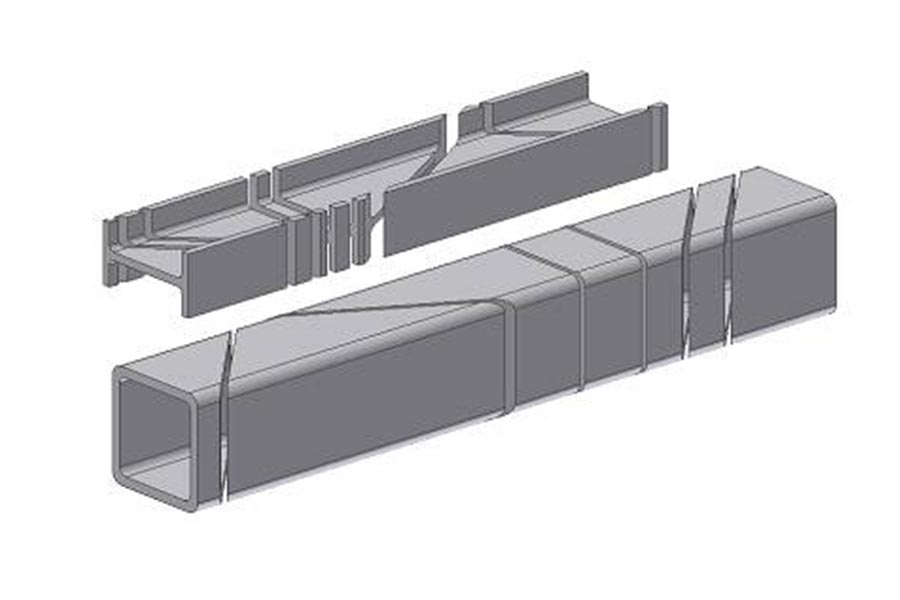

- Unique and patented double miter system

- Material is always clamped at right angles

| cutting area | mm | mm |

| 90° | 510 | 700x500 |

| 45° right | 510 | 500x500 |

| 45° left | 430 | 430x500 |

| 30° right | 320 | 320x500 |

| engine [kW] | 7.5 | |

| saw band [mm] | 6100x41x1.3 | |

| Belt speed [m/min] | 15-150 | |

| Dimension [mm] (LxWxH) | 5150x3150x2350 | |

| Material support weight [kg/m] | max 250 | |

| working height [mm] | 750 | |

- MEBA mitre system: Rotating table avoids sawing up of the material support. Material is always clamped rectangular and close up to the saw blade.

- Automatic cutting pressure and feed monitoring

- Frequency-controlled AC drive 15-150 m/min, 5.5 kW

- Hydraulic material full stroke clamping

- Automatic movement of the vice

- Automatic saw frame height adjustment

- Minimum speed and saw band monitoring

- Electric miter swiveling via servo motor

- Visualized program input with CNC control

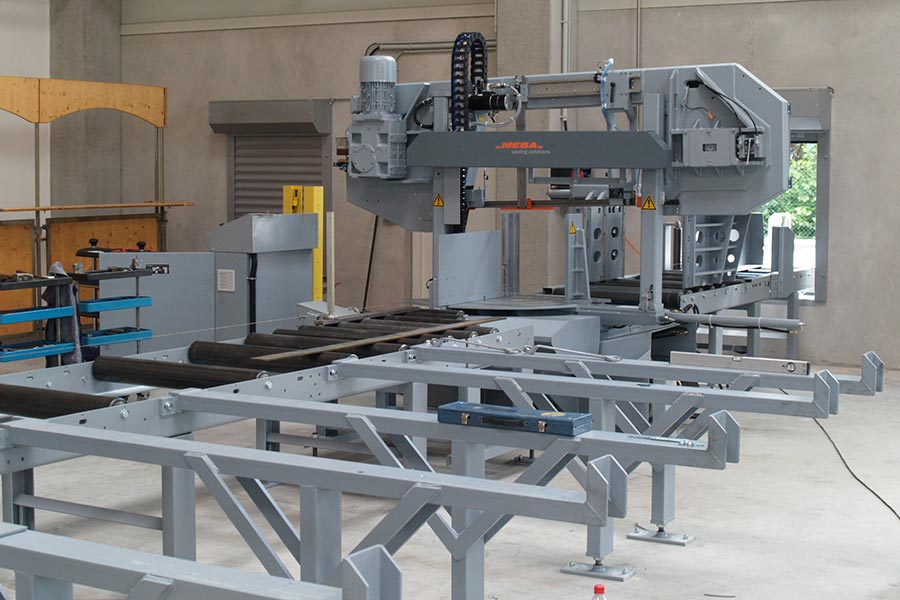

- Integrated MEBA tong insertion system from 5-2300 mm per stroke with integrated roller conveyor

| Automation level: | Serial cut |

|---|---|

| Dimensions: | 4500x3100x2200 mm |

| Max. cutting range height ↕ (mm): | 500 |

| Max. cutting range width ↔ (mm): | 430 |

| Max. cutting range Ø (mm): | 430 |

| Type: | Miter Saw |

| Schnittgeschwindigkeit: | 15 - 150 m/min |

| Reststücklänge: | 75 mm |

| Antrieb - Sägeband: | 7,5 kW |

| Sägebandspannung: | Hydraulisch |

| Sägebandabmessung: | 6100x41x1,3 mm |

| Arbeitshöhe: | 750 mm |

| Gewicht: | 3750 KG |

Login