MEBA material stand - T

Product information "MEBA material stand - T"

Material stand: T - design

Whether in the garage, at the craftsman's workshop or as support in the steel trade - our new material stands help you with concentrated power!

The solid construction - as well as the enormous support weight of 600 kg - means our material stands can be used in a variety of ways.

Design: TSuitable as an accessory for all machines

0 of 0 reviews

Login

No reviews found. Share your insights with others.

Accessories

M GASF14580

Gas strut 14-28-600

The gas spring 14-28-600 with a weight of 2.0 kg is specially designed for use in the MEBAeco 510 series. It reliably supports lifting and holding movements and ensures an even and controlled force distribution during machine operation.

✔

Perfect fit for the MEBAeco 510 series

✔

Uniform force support during lifting movements

✔

Robust design with 2.0 kg for long-lasting use

This gas pressure spring is an indispensable element for smooth movement sequences and increases the user-friendliness and safety of your machine.

E TAST70006

22QR button for opening the clamping block

This reliable button, weighing only 0.1 kg, is specially designed to open the clamping block. It offers a simple and safe way to make the work process efficient. The robust design ensures a long service life and reliable functionality in your machines. The three most important features:

✔ Lightweight at only 0.1 kg for easy handling

✔ Specially designed for opening the clamping block

✔ Robust electrical design for long-lasting use

With this button, you can optimize the operation of your machine and ensure a smooth workflow.

E TAST70002

22QR “Up Arrow” Button

The compact tree group is specially designed for demanding cleaning and processing tasks. The system weighs just 0.1 kg, making it easy to handle and flexible to use. A key component is the saw blade button, which guarantees precise control and safe operation. Thanks to its lightweight construction, adjustments can be made quickly without compromising stability or performance.

✔ Lightweight at only 0.1 kg for easy handling

✔ Sensor for electric saw frames

✔ High-quality mechanics for long-lasting use

This sensor enables simple, immediate interventions directly at the control station, increasing safety and ease of use.

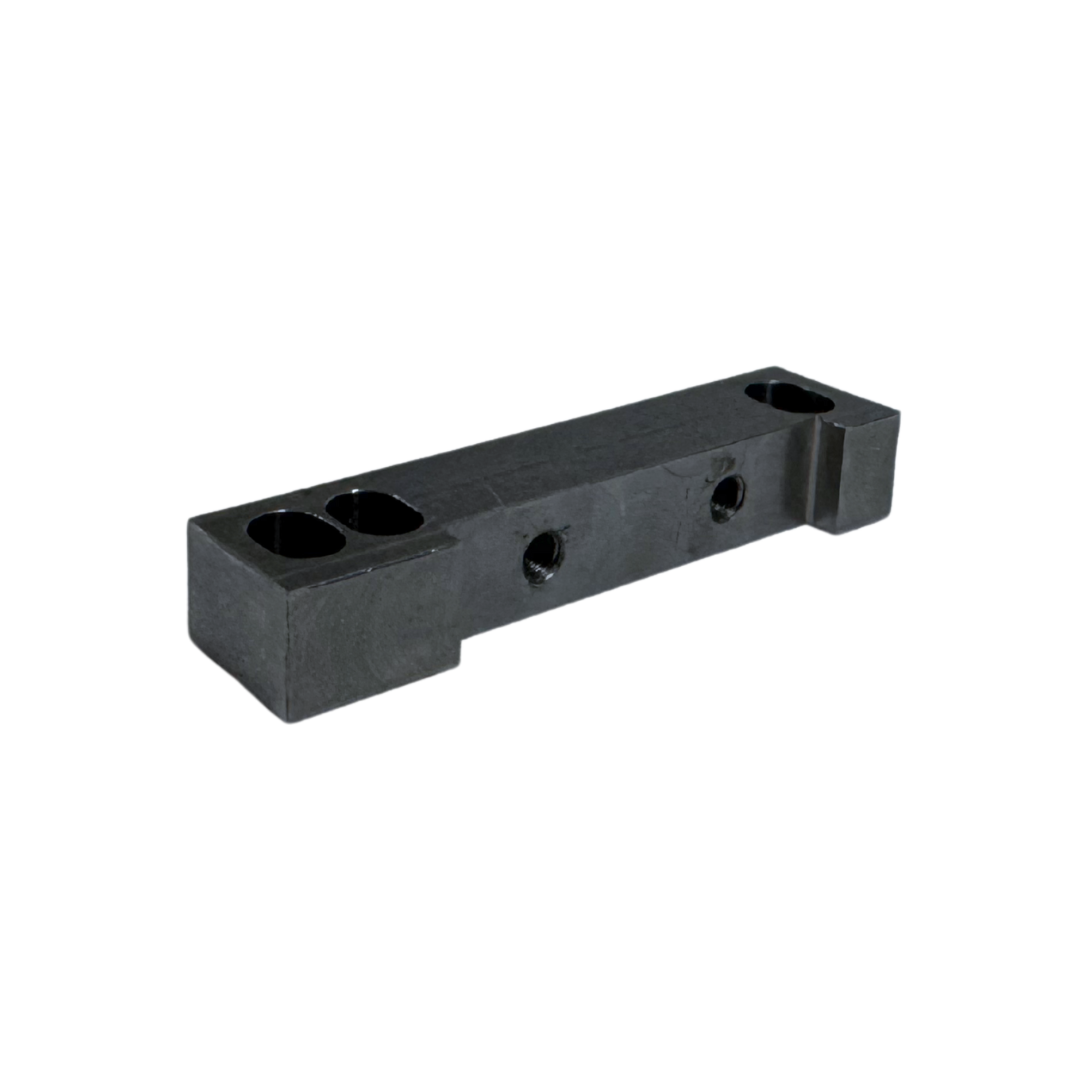

H AGGE21755

Aluminum base block (2.8 kg) for hydraulic unit H AGGR2005B. Ensures reliable pressure distribution, precise control, robust design, and easy integration into existing hydraulic systems for industrial applications.

00711 51104

Axial deep groove ball bearing 51104

The 51104 axial deep groove ball bearing is specially designed to support axial forces and is ideal for precise and durable bearing solutions in various technical applications. It impresses with its high load carrying capacity and compact design.

✔

Suitable for absorbing pure axial forces in one direction

✔

Compact design for versatile applications

✔

High running accuracy and long service life

The 51104 axial deep groove ball bearing offers a reliable solution for axial bearing arrangements and impresses with its quality and efficiency in operation.

38

%

737 0522524

Back stone for belt guide (MEBAeco 335 series, 410 series, 510 series)

✔ Weight: 0.02 kg✔ Specially developed for belt guidance in the MEBAeco 335, 410, and 510 series

✔ High-quality material for long-lasting protection and optimal guidance

This backing stone provides reliable and long-lasting support for your belt guidance systems.

00625006204

Deep groove ball bearing for MEBA pro300A, mat330, eco335, eco410, and eco510. Precision-made, high load capacity, ensures smooth movement and extends machine component life. Ideal for efficient saw operation.

F KUGE111/8F

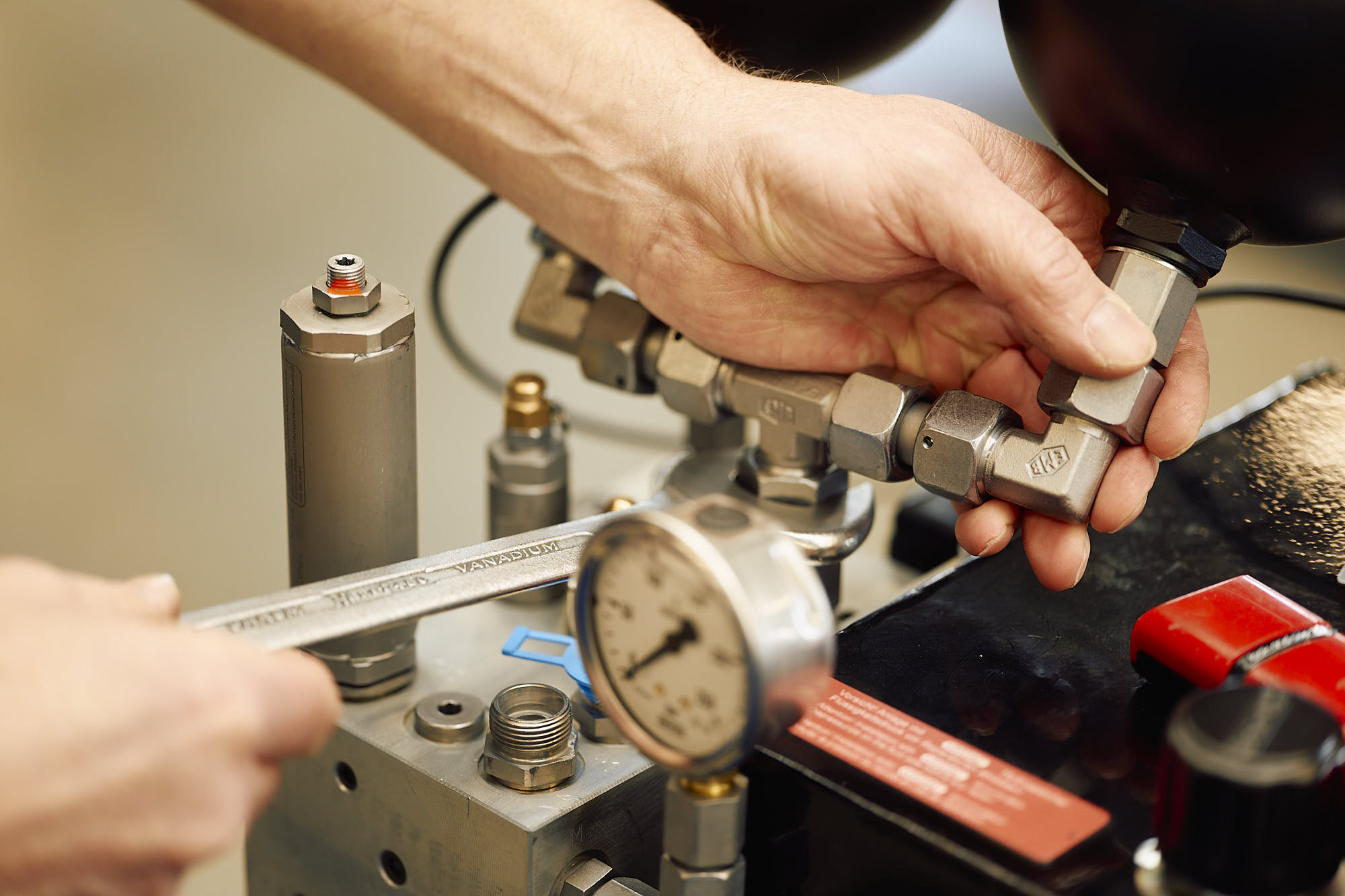

Coolant valve with 1/8" female and male thread for precise coolant flow control. Compact ball valve (0.1 kg) ensures optimal cooling, safe operation, and extended tool and machine life.

M ZAPF05201

Deflection bearing for 41 mm saw blades for precise guidance and smooth deflection. Ensures stable band run, high cutting accuracy, and extends saw blade lifespan. Ideal for maintenance and spare parts.

700 0424124

Bridge

This bridge, weighing 0.1 kg, is a precise component for use in the mechanical height adjustment bar of the MEBAeco 335 / 410 / 510 series and the MEBAswing 320 / 405 series. It contributes to exact height adjustment and positioning and thus ensures smooth operation of the height adjustment system.

✔

Compatible with MEBAeco and MEBAswing series

✔

Supports precise adjustment of the height switching strip

✔

Lightweight, robust component weighing just 0.1 kg

This bridge is an essential element for the reliable and precise functioning of the mechanical height adjustment bar in various MEBA models.

300 1485604

MEBA precision carbide guide blocks guide the saw blade.

M KSR000021

Chain tensioner for MEBAeco electric swing system. Ensures even chain tension, smooth operation, and precise, durable function. Ideal as a spare part or maintenance component for safe operation.

Tip

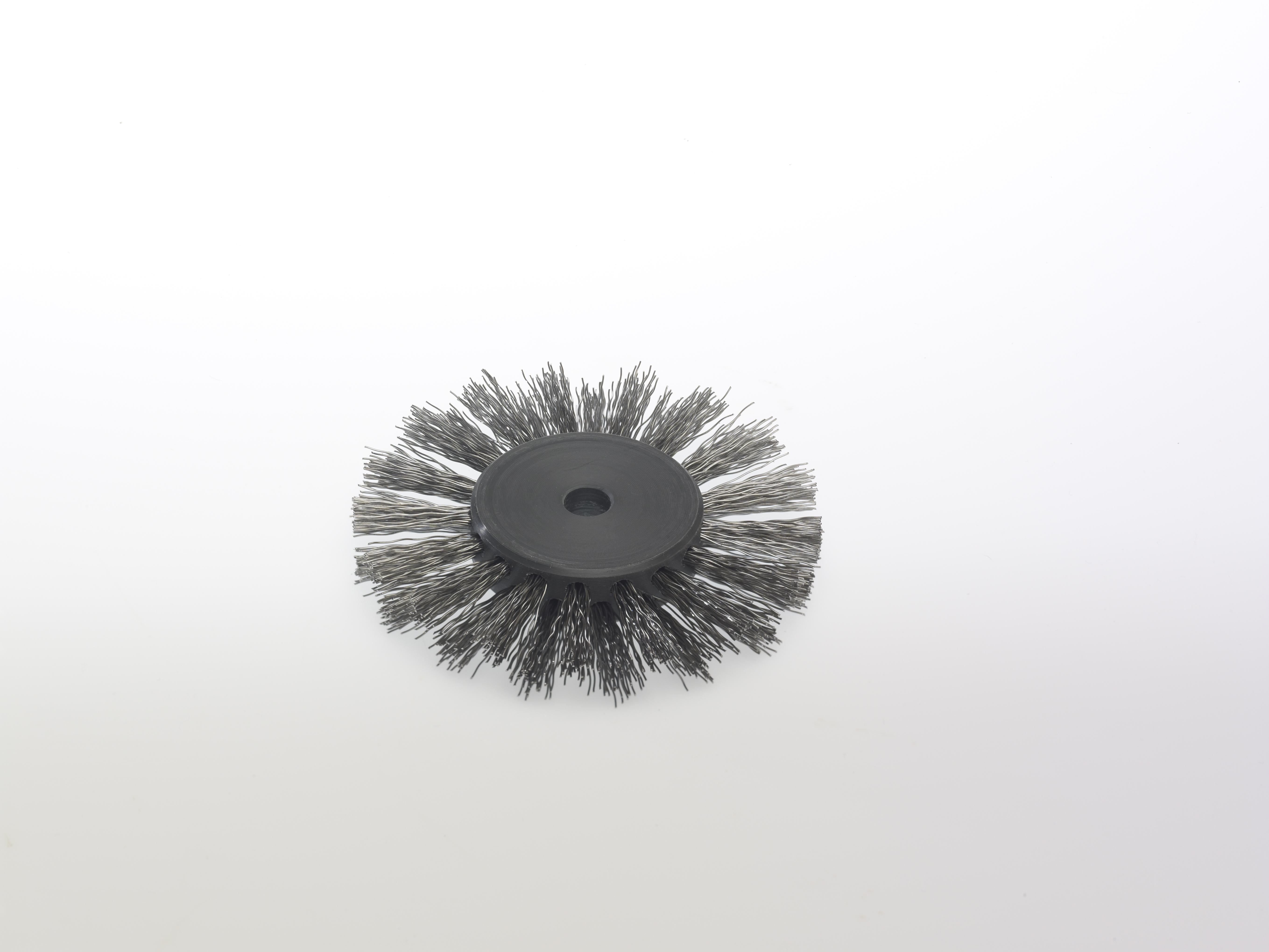

M BÜRS50000

Brass round brush for ideal saw blade cleaning. Runs synchronously with band speed, removes chips and debris, improves cut quality, and extends the lifespan of the saw blade.

Tip

M BÜRS08080

Wire round brush for optimal saw blade cleaning, Ø8 mm inner, Ø80 mm outer. Non-powered, runs synchronously with band speed, improves cut quality and extends saw blade lifespan.

Tip

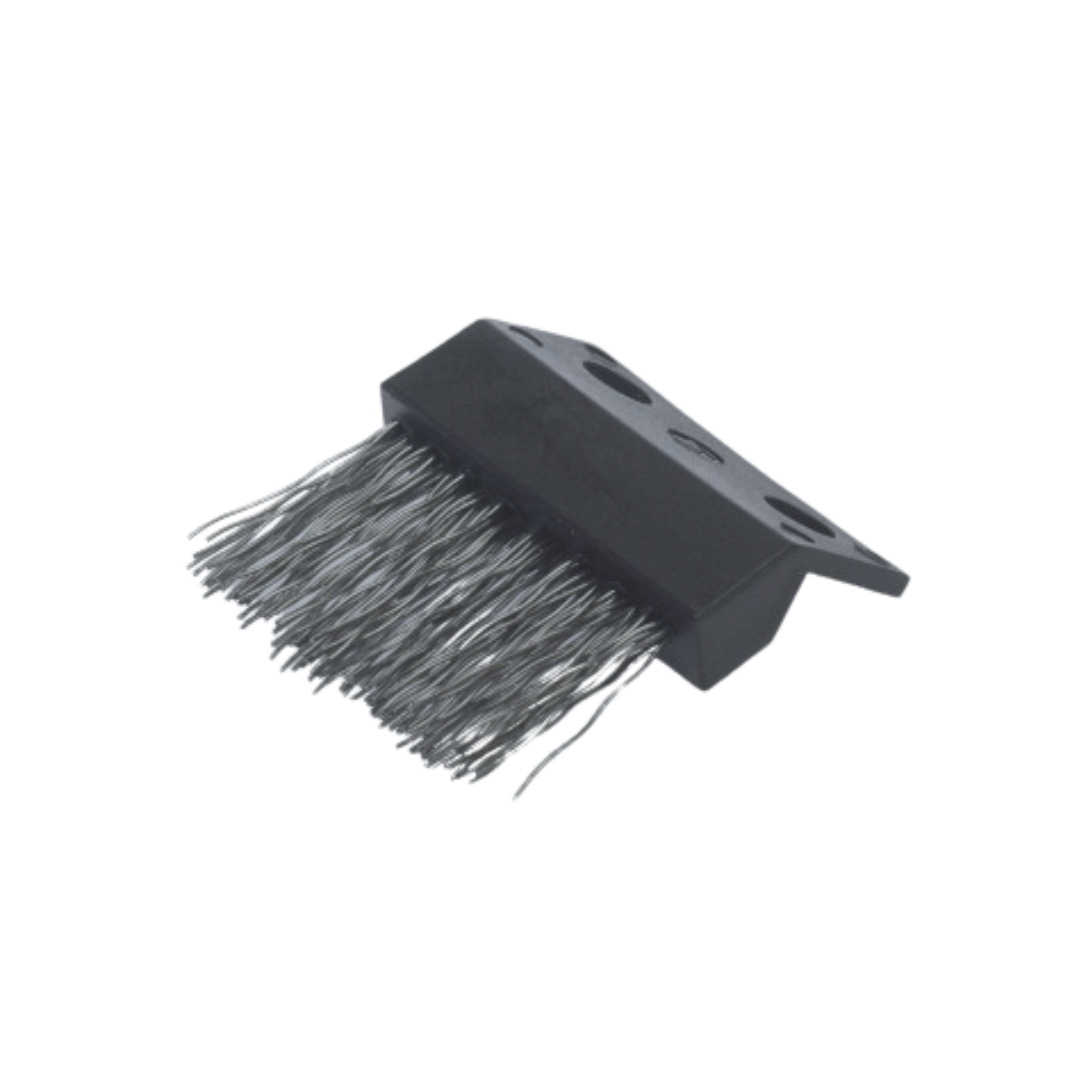

000 0003524

Flat steel brush for efficient chip removal on saw blades. Reduces residues, prevents clogging, durable and lightweight (0.01 kg). Ideal for easy handling and extended cleaning intervals.

35

%

K 612584

Complete belt guide set - consisting of FMB item no. 612584 + 612585

"Müller Teile"Weight: 1.0 KG

63

%

K 1001371

Condensate container for filter regulator (pressure reducer)"Müller Teile"Weight 0.2 KG

BAS R24000X

Connection piece right/left for MEBAbase 24 DG-HS saw

This connection piece for the right-hand side (BAS R24020X) and/or left-hand side (BAS R24030X) of the MEBAbase 24 DG-HS is specially designed for stable extension with a roller conveyor. It has a closed support surface and an integrated support foot, which ensures a secure hold and precise working height. It also serves as a connecting element for the optional BAS R24010X material roller conveyor, which is also available from our online store.

✔

Integrated support leg - ensures a secure stand and stable support

✔

Working height 900 mm - perfectly matched to the MEBAbase 24 DG-HS

✔

Connecting element for roller conveyor - prepared for simple extension with BAS R24010X

The ideal solution for professional and expandable material transport on your MEBAbase 24 DG-HS.