MEBAbase 33 DGA

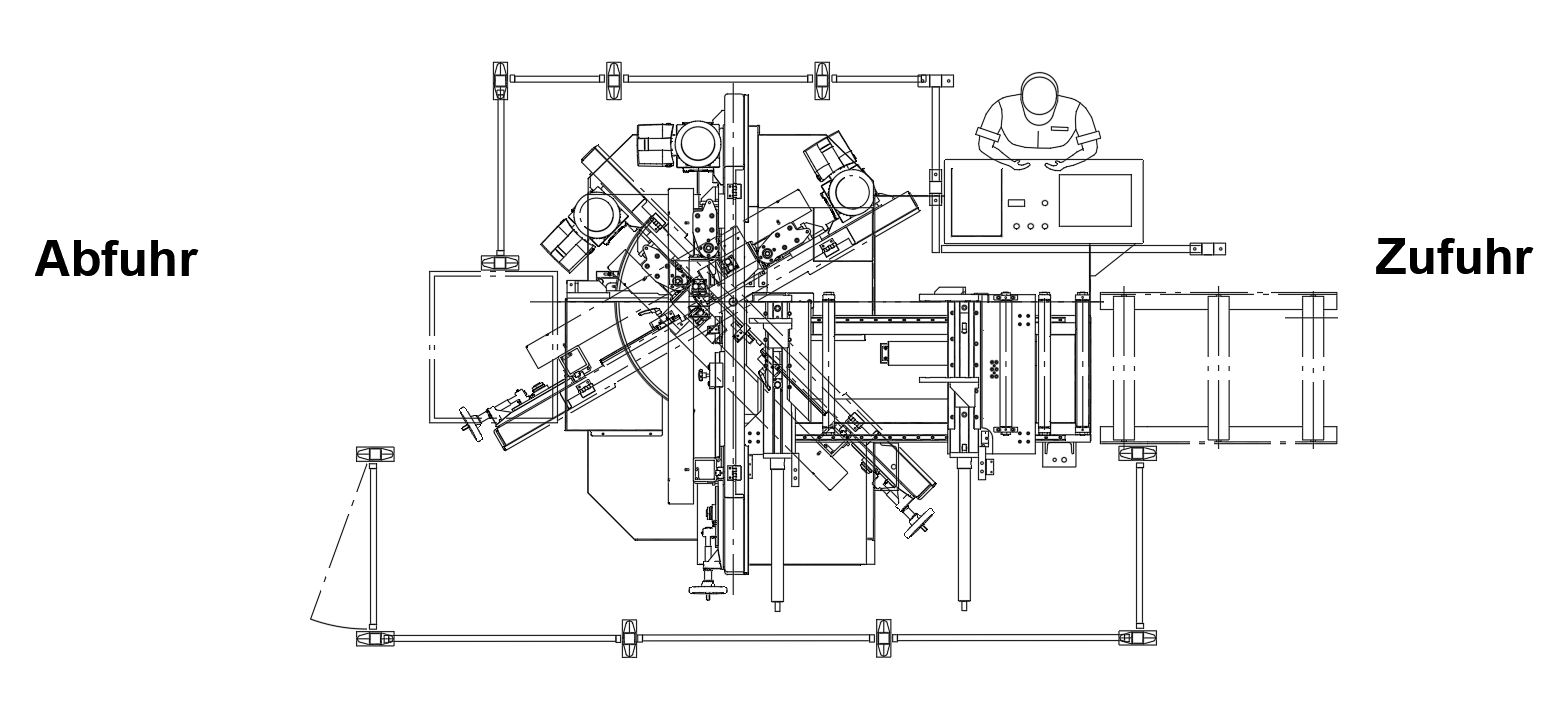

The MEBAbase 33DGA is a powerful automatic double miter saw with patented miter technology, CNC control, servo-controlled saw feed, and fully automatic sawing process - ideal for precise, efficient, and flexible cuts.

Product information "MEBAbase 33 DGA"

MEBAbase: The must-have for doers

The starter saws of the MEBAbase series are suitable for a wide range of applications and are reliable all-rounders. Whether for your hobby in the garage, craftsman or metal worker - there is something for everyone.Standard equipment

- Access protection in accordance with CE standard with protective fence

- Fully automatic sawing process with combination of length, number of pieces, miter left + right

- MEBA - Visualized program input with CNC control. Easy program creation and management of up to 255 programs.

- MEBA high-performance package: Saw feed via servo-controlled ball screw drive with automatic cutting pressure and feed monitoring, i.e., constant pressure for solid material and constant feed for thin-walled profiles.

- Fast and precise material length feed via backlash-free ball screw and servo positioning technology.

- Floating mounted insert clamp

- Electronic panning

- Rapid descent of the saw frame via push button to the edge of the material

- Patented double miter system (ERP No. 0491120): Unique automatic double miter band saw, where miters on both sides can be adjusted easily and economically by simply swiveling the saw frame and the material support.

- Automatic movement of the clamps and digital miter adjustment to 0.1°

- The miter pivot point is the intersection between the saw blade and the fixed clamping jaw, which means that the length measurement does not change when the angle position is altered

- Hydraulic full-stroke workpiece clamping. At every angle position, the material is clamped parallel at 90°, thus eliminating any force components that press the material diagonally against the fixed clamping jaws

- Stable two-column linear-guided saw frame

- Saw blade positioned at a 3° angle to the material support surface

- Saw frame clearance height adjustment automatically via height switch bar

- AC frequency-controlled band saw drive, infinitely variable from 15 to 150 m/min

- Minimum speed and saw blade breakage monitoring on the band disc

- Movable belt guide arm, adjustment to material width

- Saw blade deflection rollers - carbide guide

- Chip cleaning brush, rotating

- Saw blade tension with torque wrench

- 1 MEBA bimetal saw blade 4/6 ZpZ on machine

- CETOP hydraulic system with filter and oil control

- Microdosing system

- Modem for remote access included in delivery

- Anthracite paint finish (RAL 7016)

Optional

- Laser light for cutting line display

- Chip brush driven

- Tension pressure regulation

- Mounting elements (6x M16)

Specifications subject to change without notice.

Specifications subject to change without notice. | Product number: | BAS 3DGA000 |

|---|---|

| Automation level: | Serial cut |

| Cutting material: | Pipe, Round Stock Material |

| Cutting speed: | 15 - 150 m/min |

| Dimensions: | 2480x2300x1900 mm |

| Max. cutting range height ↕ (mm): | 335 |

| Max. cutting range width ↔ (mm): | 500 |

| Max. cutting range Ø (mm): | 335 |

| Remaining piece length: | 80 mm |

| Saw blade dimensions: | 4400x34x1,1 mm |

| Saw blade drive: | 3,0 kW |

| Saw blade tension: | Mechanical |

| Type: | Double Mitre Saw 30°-150° |

| Type series: | MEBAbase |

| Weight: | 1700 KG |

| Working height: | 750 mm |

0 of 0 reviews

Login

No reviews found. Share your insights with others.

Fitting parts

O-440034142

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-440034304

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-440034406

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-440034203

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-440034508

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

OS440034406

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OS440034304

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OS440034203

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OS440034507

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OX440034304

The Performance + band saw blade impresses with its tooth profile

for easier sawing with reduced feed rates. It withstands higher cutting temperatures and downforce, giving it extremely high wear resistance.

wear resistance.Field of application: DThick-walled profiles, steels and non-ferrous metals, materials

with tensile strengths of up to 1,400 N/mm², stainless and acid-resistant steels,

high feed rates, shortened sawing timese.g: Structural steel, deep-drawing steel, free-cutting steel, ball bearings

and unalloyed tool steel. Aluminum, copper and brass,

High-speed steel and cold work steel. Nitriding steel, stainless and

acid-resistant steels. TitaniumMaterial: M42Tooth shape: Normal

For customers who value a long service life and shorter sawing times.

sawing times.

OX440034203

The Performance + band saw blade impresses with its tooth profile

for easier sawing with reduced feed rates. It withstands higher cutting temperatures and downforce, giving it extremely high wear resistance.

wear resistance.Field of application: DThick-walled profiles, steels and non-ferrous metals, materials

with tensile strengths of up to 1,400 N/mm², stainless and acid-resistant steels,

high feed rates, shortened sawing timese.g: Structural steel, deep-drawing steel, free-cutting steel, ball bearings

and unalloyed tool steel. Aluminum, copper and brass,

High-speed steel and cold work steel. Nitriding steel, stainless and

acid-resistant steels. TitaniumMaterial: M42Tooth shape: Normal

For customers who value a long service life and shorter sawing times.

sawing times.

OX440034406

The Performance + band saw blade impresses with its tooth profile

for easier sawing with reduced feed rates. It withstands higher cutting temperatures and downforce, giving it extremely high wear resistance.

wear resistance.Field of application: DThick-walled profiles, steels and non-ferrous metals, materials

with tensile strengths of up to 1,400 N/mm², stainless and acid-resistant steels,

high feed rates, shortened sawing timese.g: Structural steel, deep-drawing steel, free-cutting steel, ball bearings

and unalloyed tool steel. Aluminum, copper and brass,

High-speed steel and cold work steel. Nitriding steel, stainless and

acid-resistant steels. TitaniumMaterial: M42Tooth shape: Normal

For customers who value a long service life and shorter sawing times.

sawing times.

OD440034406

The material + saw blade impresses with its precision

due to the ground positive rake angle and ground tooth gaps.

This reduces the cutting force at higher cutting speeds.

is reduced. Due to the cutting accuracy, it has a high load capacity in terms of

duration, heat and wear.

Field of application: FFor demanding cutting conditions, materials with tensile strengths of up to 1,700 N/mm².

tensile strengths of up to 1,700 N/mm², high-alloy materials, bronzes,

titanium alloyse.g.: rust- and acid-resistant steels,

Nickel-based alloysMaterial: M51Tooth shape: Normal

The Material+ has an aggressive tooth geometry

- which, in conjunction with the harder cutting edge material M51, is suitable for particularly

is suitable for particularly demanding materials.

OD440034203

The material + saw blade impresses with its precision

due to the ground positive rake angle and ground tooth gaps.

This reduces the cutting force at higher cutting speeds.

is reduced. Due to the cutting accuracy, it has a high load capacity in terms of

duration, heat and wear.

Field of application: FFor demanding cutting conditions, materials with tensile strengths of up to 1,700 N/mm².

tensile strengths of up to 1,700 N/mm², high-alloy materials, bronzes,

titanium alloyse.g.: rust- and acid-resistant steels,

Nickel-based alloysMaterial: M51Tooth shape: Normal

The Material+ has an aggressive tooth geometry

- which, in conjunction with the harder cutting edge material M51, is suitable for particularly

is suitable for particularly demanding materials.

OD440034304

The material + saw blade impresses with its precision

due to the ground positive rake angle and ground tooth gaps.

This reduces the cutting force at higher cutting speeds.

is reduced. Due to the cutting accuracy, it has a high load capacity in terms of

duration, heat and wear.

Field of application: FFor demanding cutting conditions, materials with tensile strengths of up to 1,700 N/mm².

tensile strengths of up to 1,700 N/mm², high-alloy materials, bronzes,

titanium alloyse.g.: rust- and acid-resistant steels,

Nickel-based alloysMaterial: M51Tooth shape: Normal

The Material+ has an aggressive tooth geometry

- which, in conjunction with the harder cutting edge material M51, is suitable for particularly

is suitable for particularly demanding materials.