MEBAeco 335 GA

MEBAeco: Ready-made individuality

2-column automatic metal band saw with infinitely variable miter adjustment from 90° to 30°. The MEBAeco 335 GA automatic miter band saw is universally applicable, ergonomically designed, and offers excellent value for money. The machine control system complies with CE standard 89/289.Standard equipment

- Access protection in accordance with CE standard via protective fence

- Fully automatic sawing process after entering the length and setting the number of pieces

- Workpiece clamping-sawing-ramping up-positioning

- Manual miter adjustment from 90° to 30°, infinitely variable according to scale

- The miter pivot point is the intersection between the saw blade and the material support, which means that the length measurement does not change when the angle position is altered.

- MEBA high-performance package: Saw feed via frequency-controlled spindle drive with automatic cutting pressure and feed monitoring. This ensures optimum conditions for every sawing task, i.e., constant pressure for solid material and constant feed for thin-walled profiles.

- Hydraulic full-stroke material clamping

- Quick material clamping

- The material is clamped parallel at 90° for every angle setting of the saw frame.

- Automatic operation also possible with miter setting

-

Stable two-column linear-guided saw frame

- Saw blade positioned at a 3° angle to the material support surface

- Central machine control

- Automatic saw frame clearance height adjustment

- Minimum speed and saw blade breakage monitoring on the band disc

- AC frequency-controlled band saw drive, infinitely variable from 15 to 150 m/min

- Electronic PLC control

- Menu-driven, intelligent 4.3" touchscreen control via Windows CE 6.0 operating system: Program memory for 1000 data records; Continuous bus networking; Option to switch between units of measurement; Documentation and information on faults and warnings

- Automatic cutting channel calculation with double stroke function Material length feed via backlash-free ball screw and servo positioning technology. Positioning accuracy 0.1 mm

- Adjustment of insertion speed depending on material weight

- Built-in operating hours counter

- Material feed function for short non-productive times—no need to re-clamp the material for short sections

- Material section length: Single stroke up to 600 mm, multiple strokes up to 9999 mm

- Movable belt guide arm, adjustment to material width

- Saw blade deflection rollers - carbide guide

- Chip cleaning brush, rotating

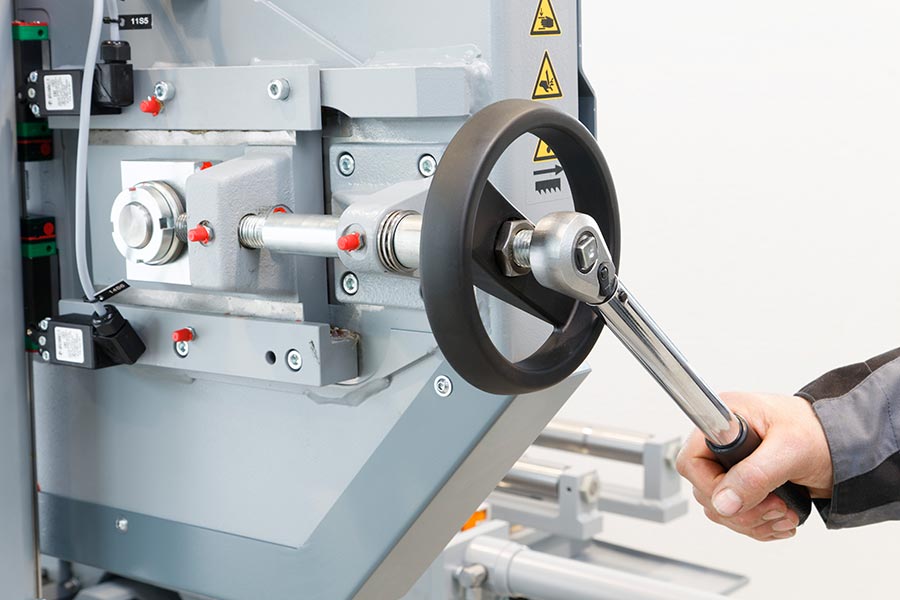

- Saw blade tension with torque wrench

- Operating instructions and spare parts list (digital)

-

1 MEBA bimetal saw blade 4/6 ZpZ on machine

- Coolant system (approx. 100 liters). Can be combined with MEBA Eco micro-dosing system as an option

- Silver gray/blue gray paint finish (RAL 7001/RAL 7031)

- Modem for remote access including dashboard (overview of all relevant machine data) included in delivery. Term: 1 year. (Valid only for machines located in Germany: includes final maintenance after warranty expires. During the warranty period, the modem remains the property of MEBA.)

- Laser light for cutting line display/scoring saws

- Chip brush driven

- Microdosing system

- Tension pressure regulation with fixed control panel

- Hydraulic material bundle tension 335 GA

- 7" CE Panel MEBAeco 335 GA

- Zero stop (automatic 0 positioning)

- Control panel set up separately, cable length 2.5 m

- LED work light

- Measuring stop 0 - 500 mm

- Special two-color paint finish according to RAL chart

- Hydraulic saw blade tensioning 335 GA

- Scraper belt conveyor for optimal chip disposal

- Mobile chip tipping container for forklift transport

- Opening the slide-in clamping device on both sides

- Grooved clamping strips for 335 GA, ES, and HS

- Water spray gun

- Compressor for microdosing system

- Heating for hydraulics

- Heating coolant

- Mounting elements (6x M16)

- Additional doors in the protective fence

- Section slide swinging along

- Hydraulic miter clamping including digital miter cut control

- USB port

- MEBA NC Server: External Postprocessor: Data Exchange OPC-UA for P300 incl. 10 m patch cable

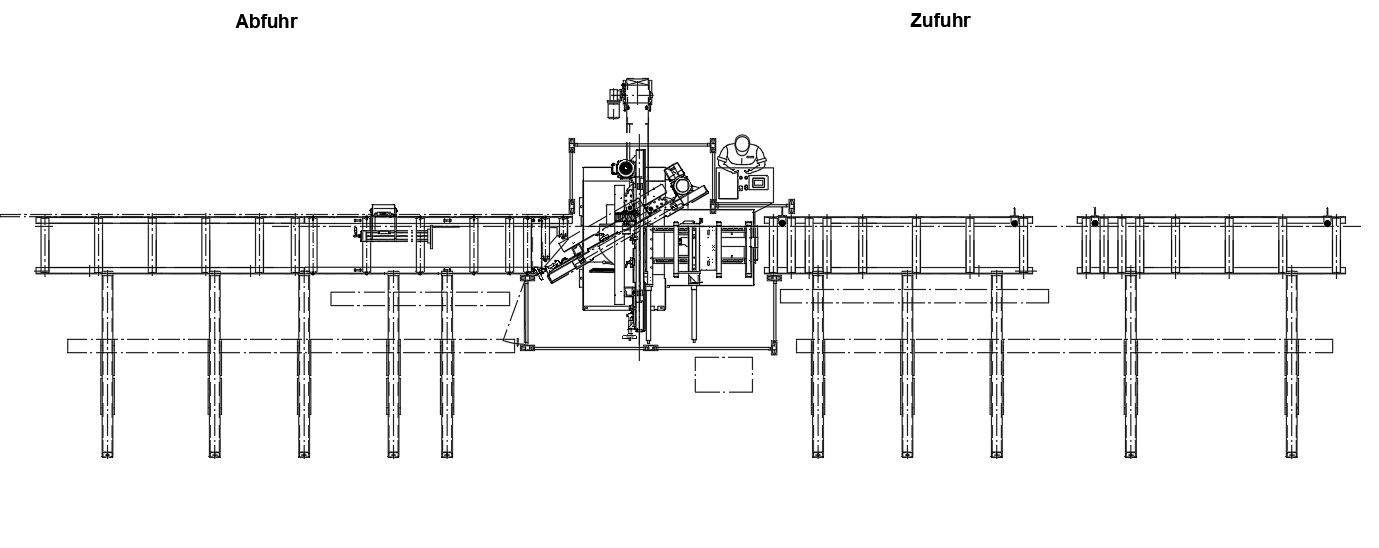

- Rollenbahnen sind in verschiedenen Längen verfügbar

Specifications subject to change without notice.

Specifications subject to change without notice.| Product number: | 335 GA00020 |

|---|---|

| Automation level: | Serial cut |

| Cutting material: | Pipe, Round Stock Material |

| Cutting speed: | 15 - 150 m/min |

| Dimensions: | 2230x2200x1900 mm |

| Max. cutting range height ↕ (mm): | 335 |

| Max. cutting range width ↔ (mm): | 500 |

| Max. cutting range Ø (mm): | 335 |

| Remaining piece length: | 65 mm |

| Saw blade dimensions: | 4400x34x1,1 mm |

| Saw blade drive: | 3,0 kW AC |

| Saw blade tension: | Mechanical |

| Type: | Miter Saw |

| Type series: | MEBAeco |

| Weight: | 1510 KG |

| Working height: | 750 mm |

Login