MEBAeco 510 DGA-2300

MEBAeco: The allrounder

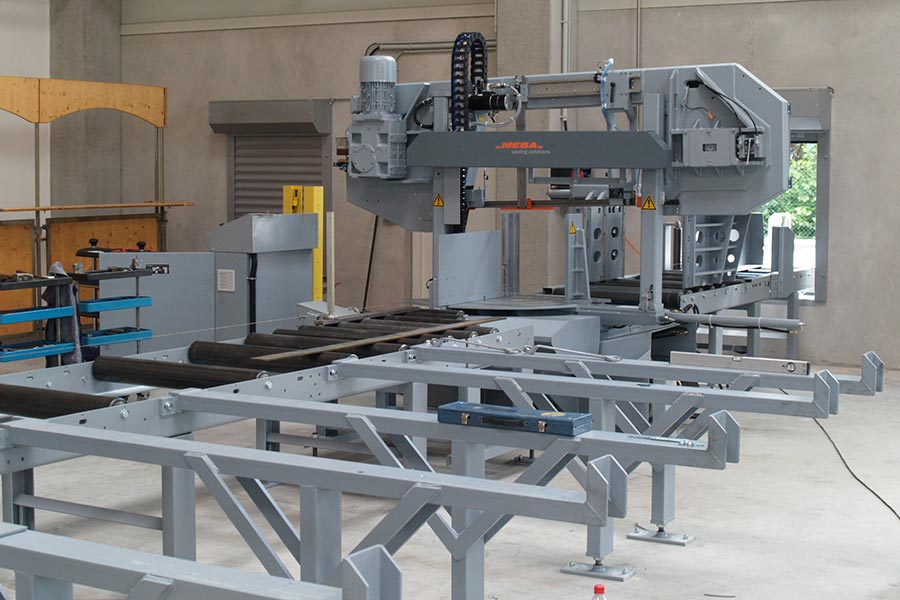

Two-column linear-guided double-miter metal band saw automatic with patented miter system (ERP No. 0491120). Particularly suitable for versatile use with different cross-sections, materials, and frequently changing miter cuts.- Access protection according to CE standard via light barrier

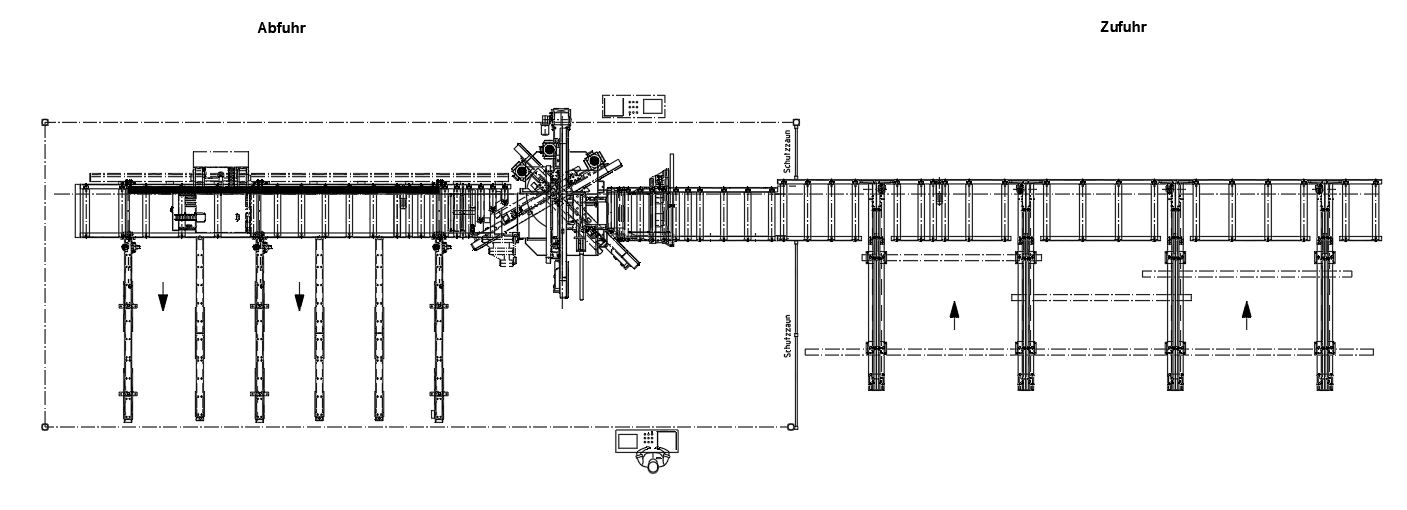

- MEBA band saw automatic in proven two-column linear design with integrated MEBA clamp feed system from 5–2300 mm per stroke (extendable in 1000 mm increments)

- MEBA visualized program input with CNC control. Fully automatic operation at any angle setting 30°–135°, length, and quantity. Easy program creation and management of up to 255 programs. Operators enter the sawing task in the display mask using a cut diagram. Input errors are minimized, enabling simple and secure creation of production orders by different operators.

- MEBA high-performance package: saw feed via servo-controlled ball screw drive with automatic monitoring of cutting pressure and feed, ensuring optimal conditions for every sawing task, i.e., constant pressure for solid material and constant feed for thin-walled profiles

- Fast and precise material length feed via rack and AC drive with a maximum stroke length of 2300 mm and integrated roller conveyor up to 3000 mm

- Double-sided opening of the clamping jaws of the clamp feed system; serrated bars for heavy material transport

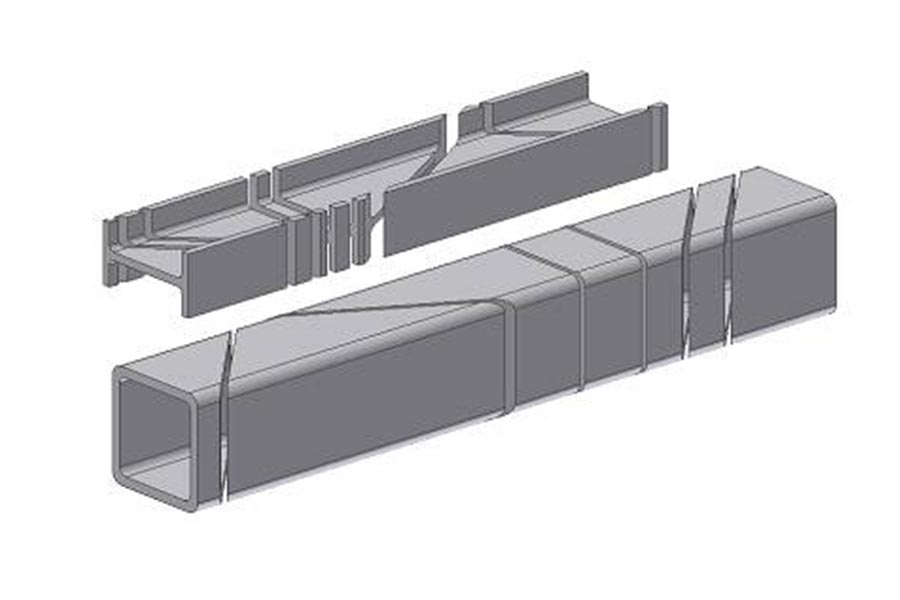

- Saw frame in massive, low-vibration welded steel construction; saw blade set at a 3° angle to the material support surface for highest cutting performance and long service life when cutting structural steel profiles

- Combined saw blade guidance, precision bearings for low-wear band deflection; beveled carbide sliding guides for saw blade guidance

- Miter pivot point (0-point) is at the intersection of the saw blade and fixed clamping jaw, preventing any change in length when the angle is adjusted; automatic compensation of cut kerf at every angle

- NC angle programming at the control panel (freestanding in these machines)

-

Patented double-miter clamp system (ERP No. 0491120) with automatic clamp movement. The material clamp moves automatically in the feed direction according to the desired miter, ensuring the material is always clamped square and close to the saw blade. Material clamping is performed with full-stroke cylinders

-

Rapid lowering of the saw frame via automatic height switch bar down to just above the material. In series cutting, the saw frame moves only slightly above the material, allowing positioning of a new section. Optimized cycle times for single and series cuts

-

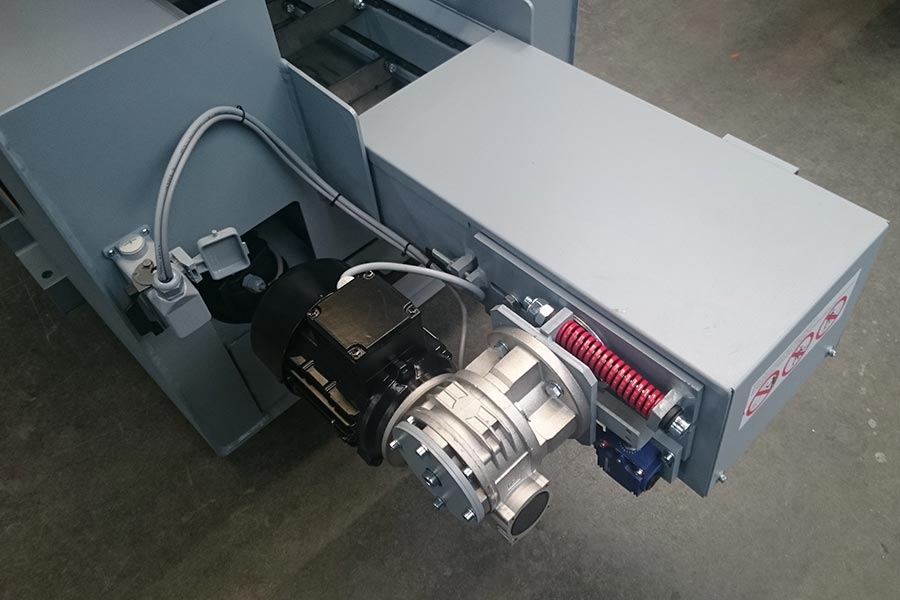

AC frequency-controlled saw blade drive, continuously adjustable 15–150 m/min

-

Saw blade set at a 3° angle to the material support surface.

-

Preloaded, maintenance-free ball recirculating linear guides on the material feed and saw frame feed for smooth, jerk-free, and vibration-damped feed

-

Separately positioned control panel

-

Movable band guide arm, adjustable to material width

-

Chip cleaning brush running with the saw

-

Chip cleaning brush running with the saw

-

Operating manual and spare parts list (digital)

-

1 MEBA bimetal saw blade 4/6 TPI supplied with the machine

-

CETOP hydraulic system

-

Coolant system (approx. 100 liters), optionally combinable with MEBA micro-dosing system

-

Paint finish silver gray / blue gray (RAL 7001 / RAL 7031)

-

Modem for remote access including dashboard (overview of all relevant machine data) included. Duration 1 year (valid only for machine location in Germany: including final maintenance after warranty period. During warranty, the modem remains the property of MEBA)

-

Laser pointer for cut line marking / layout cuts

-

Driven chip brush

-

Micro-dosing system

-

Clamping pressure regulation for separately positioned control panel

-

Material bundle clamping MEBA 510 DGA-2300

-

Job menu

-

Material database

- USB interface

- MEBA NC Server comfort package

-

OPC-UA data exchange for P500

-

Zero stop (automatic 0-positioning)

-

LED work light

-

Special 2-color paint finish according to RAL chart

-

Chip conveyor for optimal chip removal

-

Mobile chip tipping container for forklift transport

-

Cut progress monitoring MEBAeco 410 DGA / 510 DGA

-

Water spray gun

-

Compressor for micro-dosing system

-

Heating for hydraulic unit

-

Coolant heater

-

Control cabinet heater

-

Setup elements (4 pieces)

-

Adjustable deflection plate 510 DGA

- Roller conveyors available in various lengths

Specifications subject to change without notice.

Specifications subject to change without notice.| Product number: | 510 DGA23F2 |

|---|---|

| Automation level: | Serial cut |

| Cutting material: | Pipe, Round Stock Material, Round solid material, Square solid material |

| Cutting speed: | 15 - 150 m/min |

| Dimensions: | 4500x3100x2000 mm |

| Max. cutting range height ↕ (mm): | 500 |

| Max. cutting range width ↔ (mm): | 700 |

| Max. cutting range Ø (mm): | 430 |

| Remaining piece length: | 75 mm |

| Saw blade dimensions: | 6100x41x1,3 mm |

| Saw blade drive: | 7,5 kW |

| Saw blade tension: | Hydraulic |

| Type: | Double Mitre Saw 30°-150° |

| Type series: | MEBAeco |

| Weight: | 3700 KG |

| Working height: | 750 mm |

Login