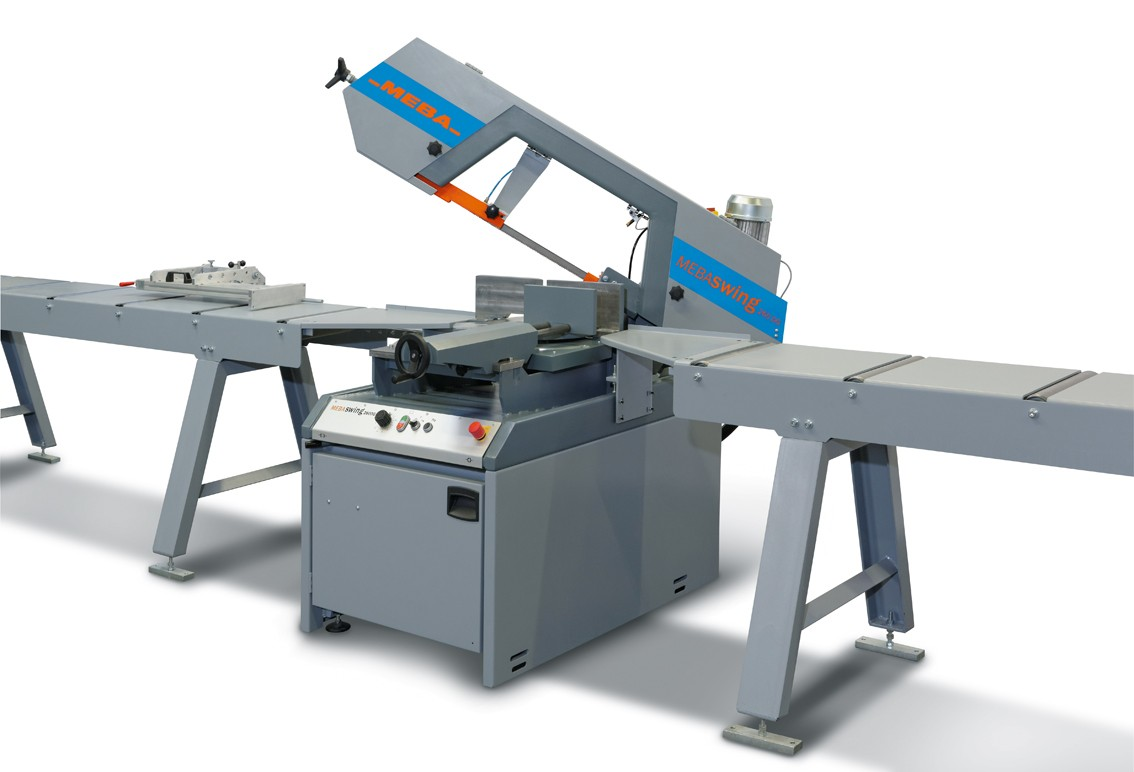

MEBAswing 260 DG

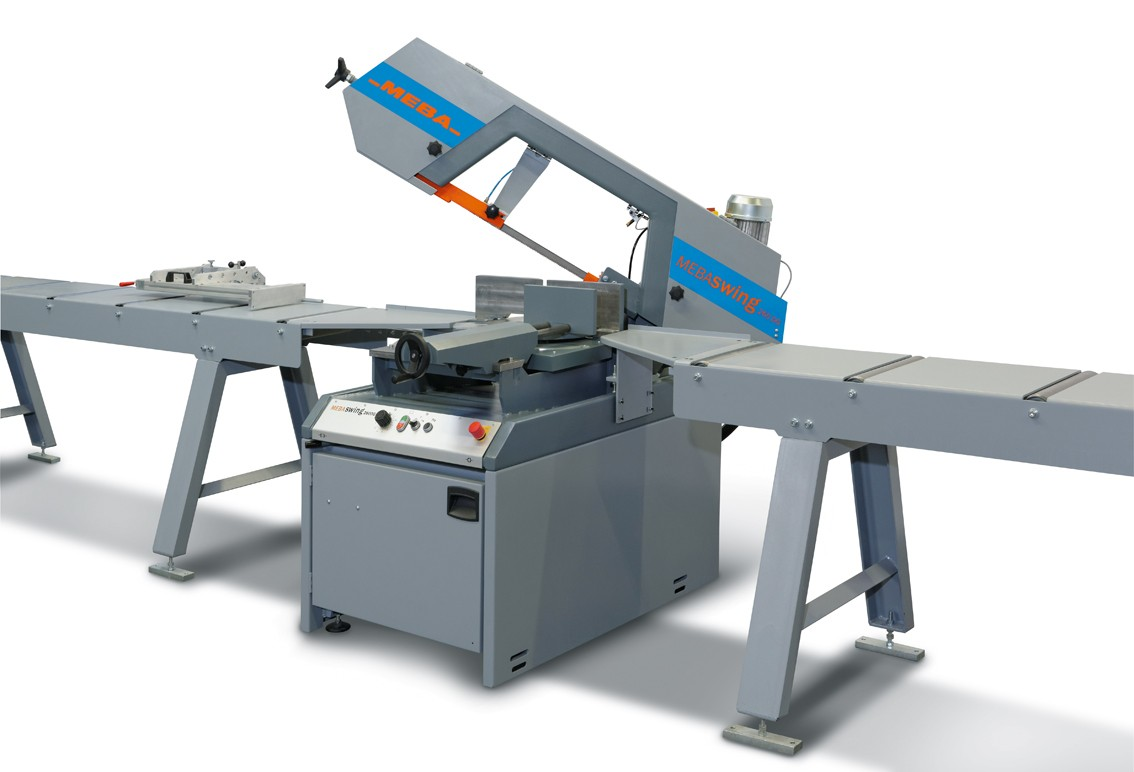

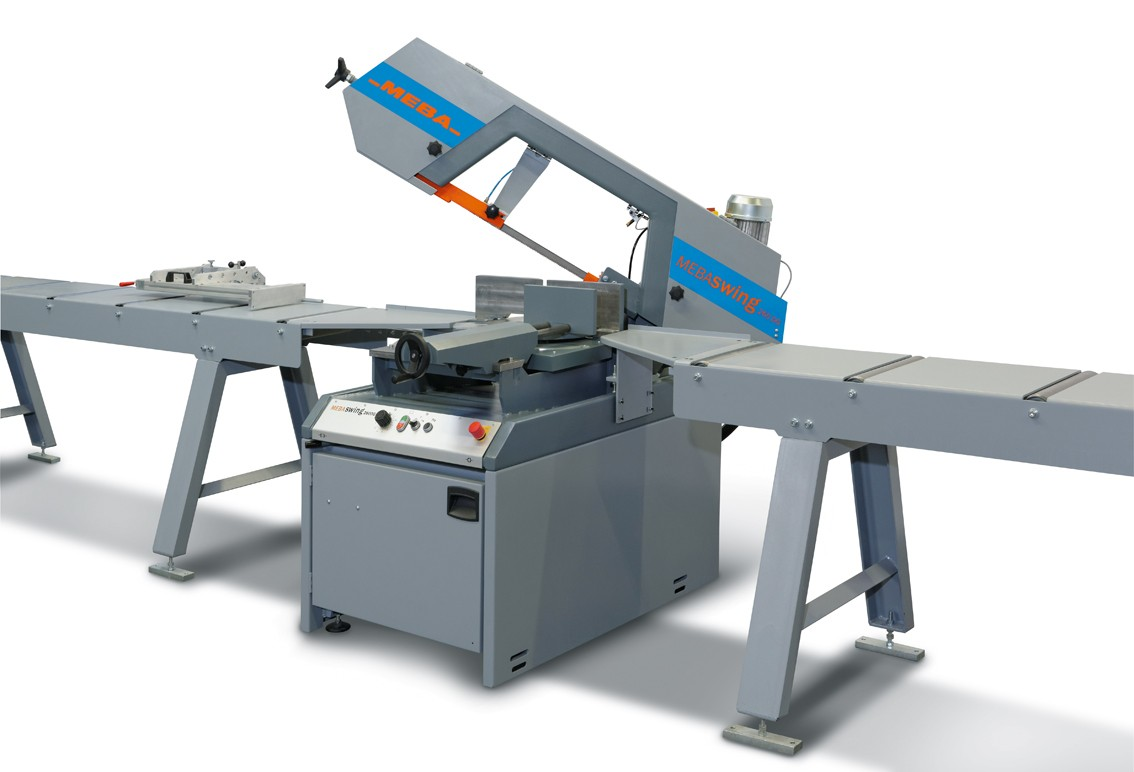

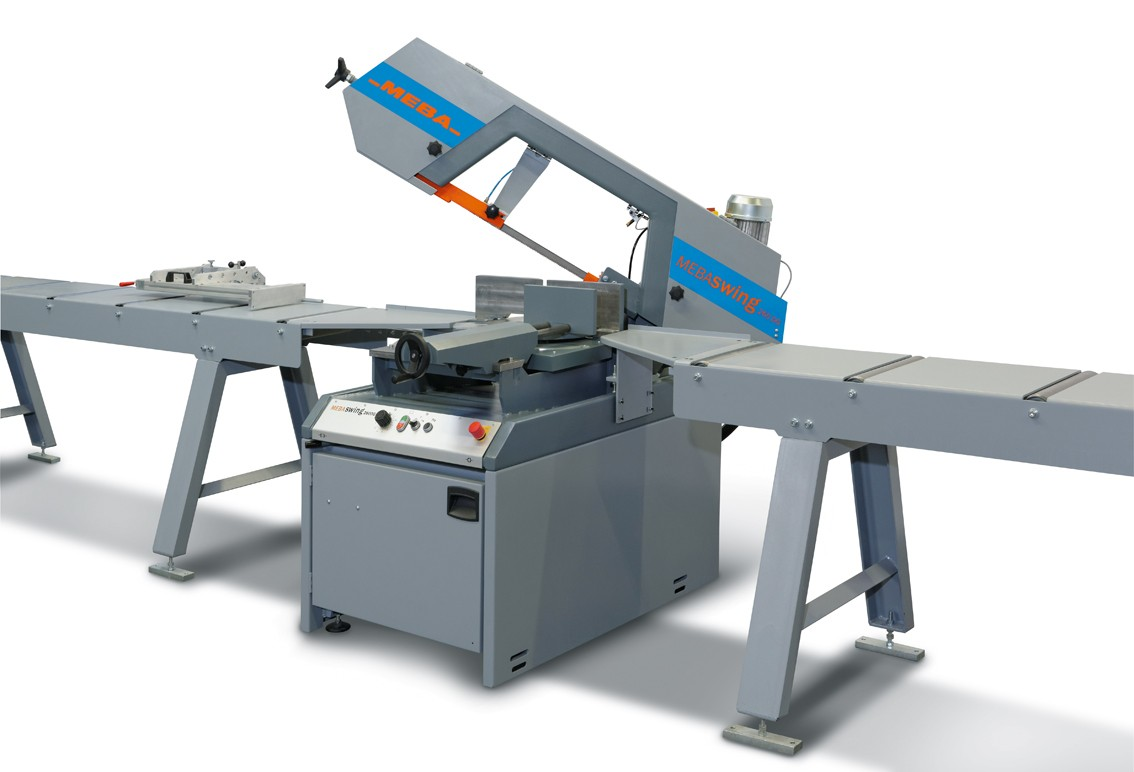

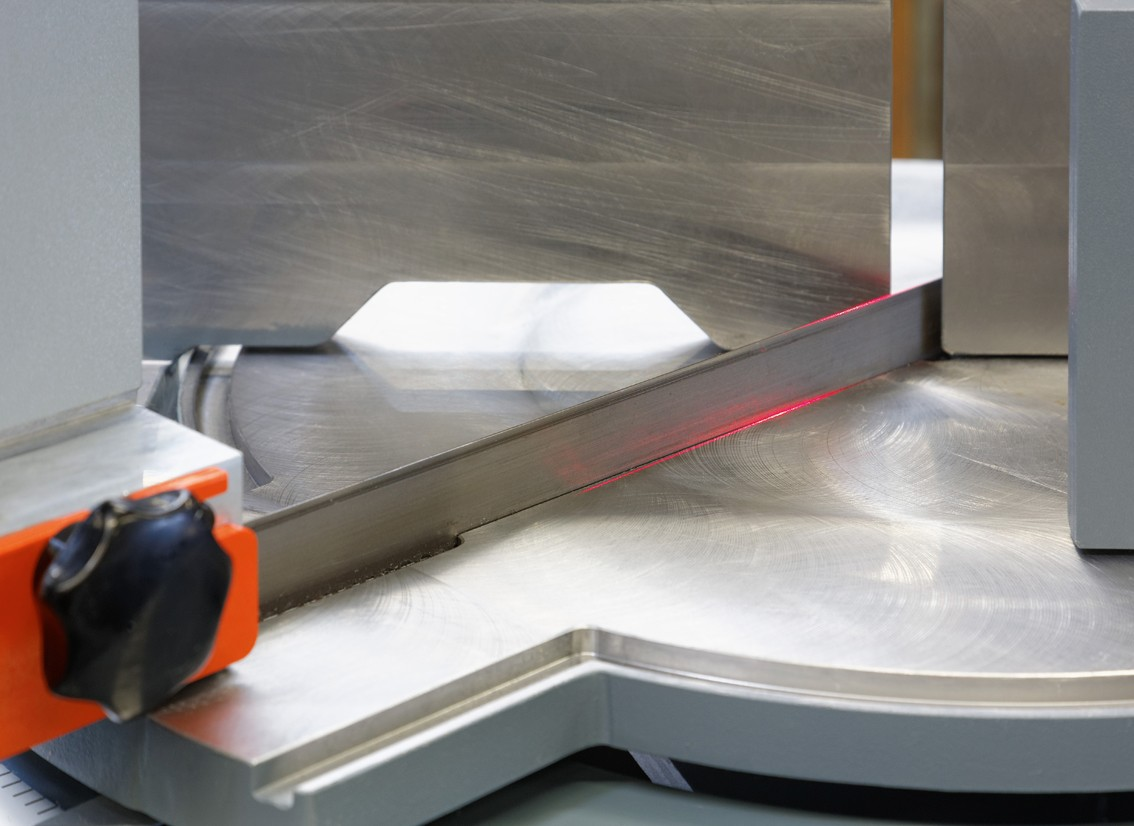

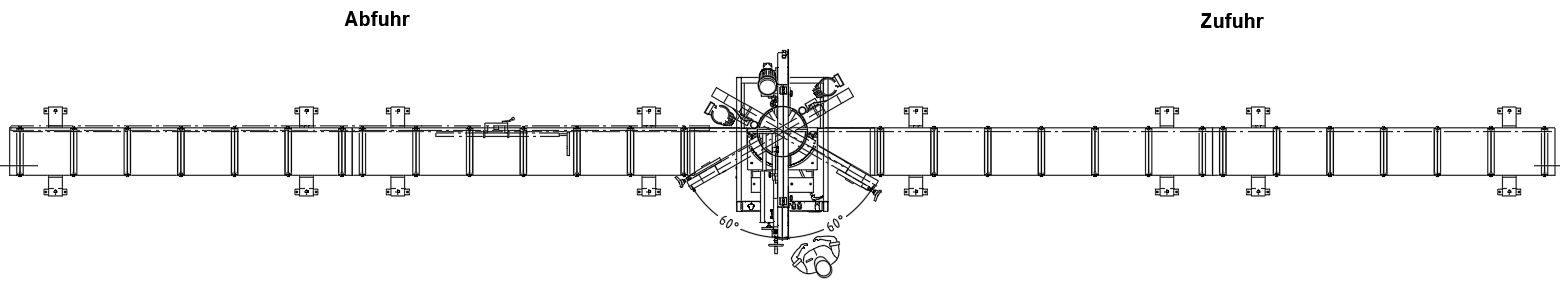

The MEBAswing 260 DG is a versatile miter bandsaw with stepless 30°–150° adjustment, ergonomic operation, and precise cutting – ideal for changing materials, profiles, and flexible workshop applications.

Product information "MEBAswing 260 DG"

Der Universalhelfer: clever und unkompliziert

The universally applicable MEBAswing 260 DG miter band saw machine features an ergonomically advanced design and an optimal price-performance ratio. It is particularly suitable for versatile use with different cross-sections, materials, and frequently changing miter cuts. The machine control complies with CE standard 89/289.Standard equipment

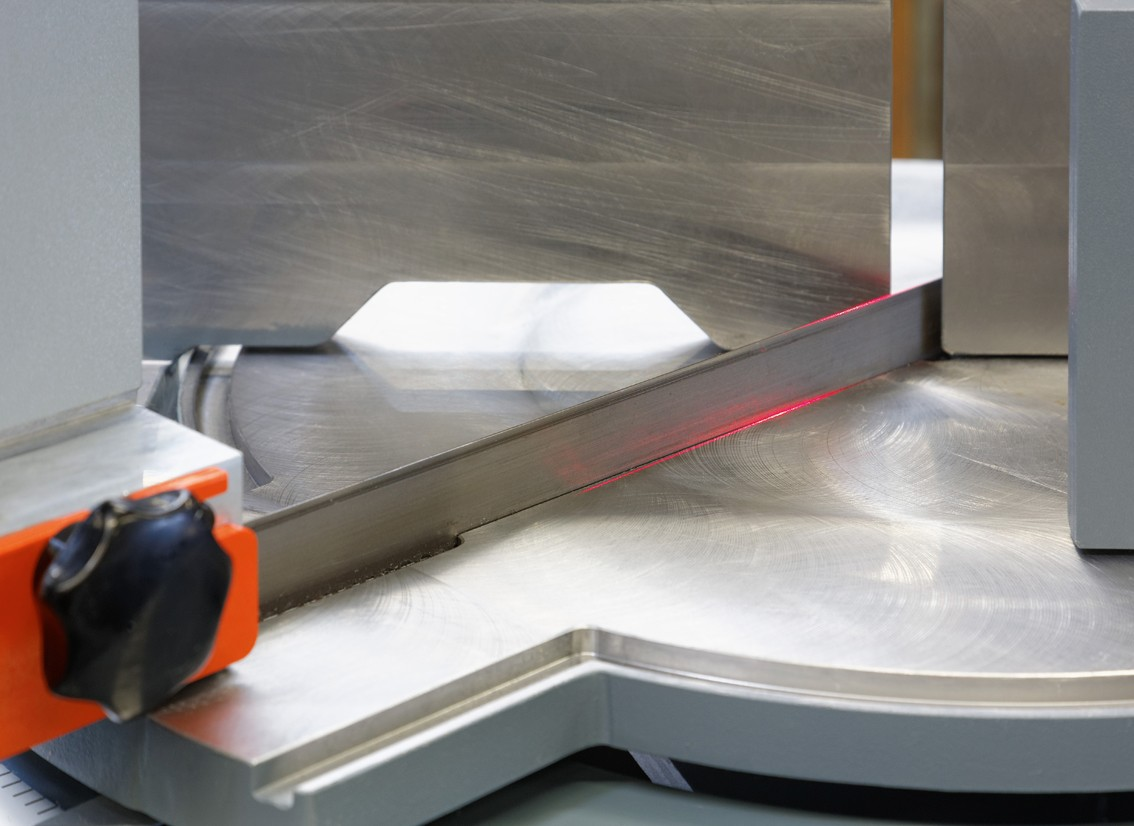

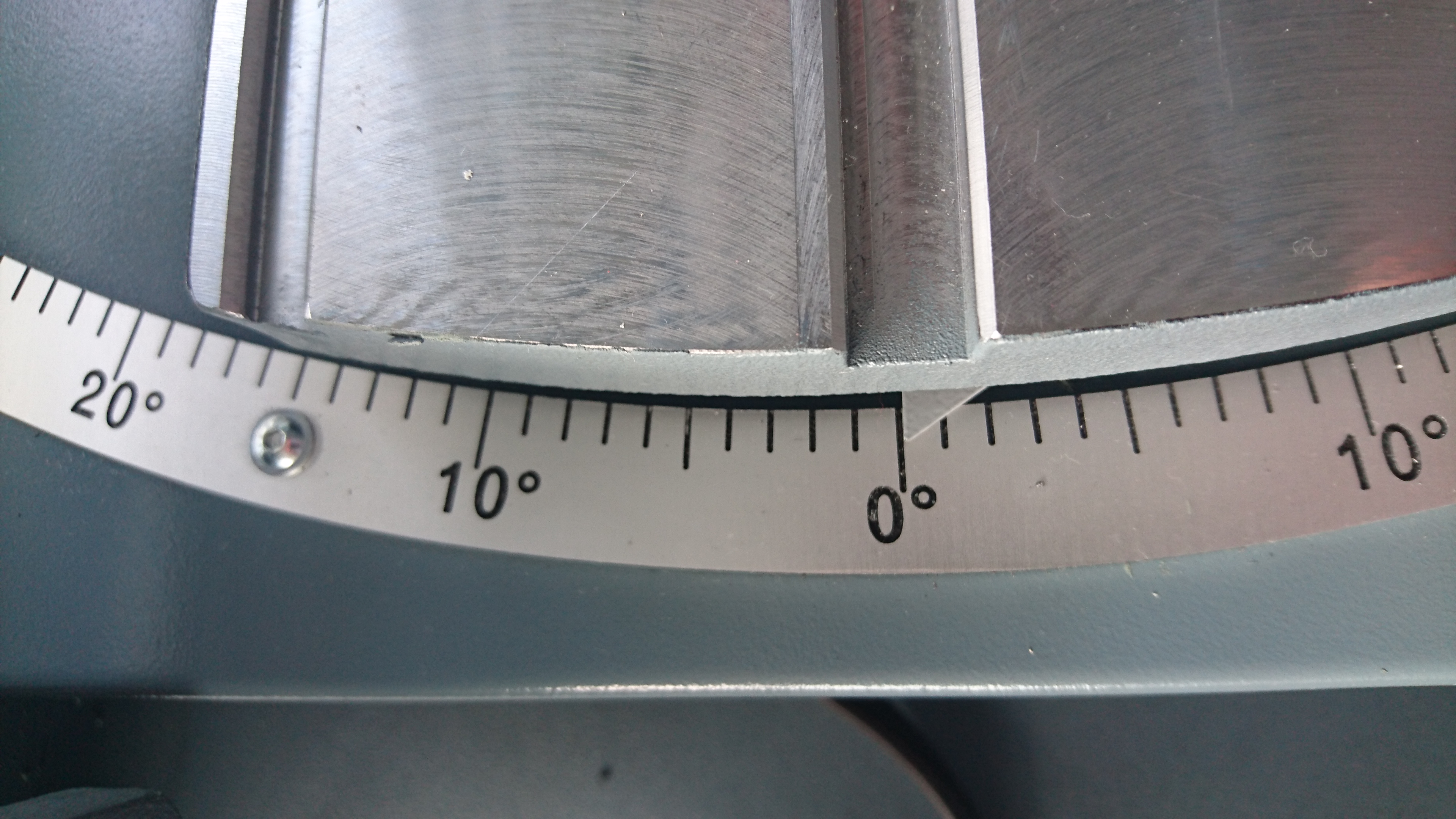

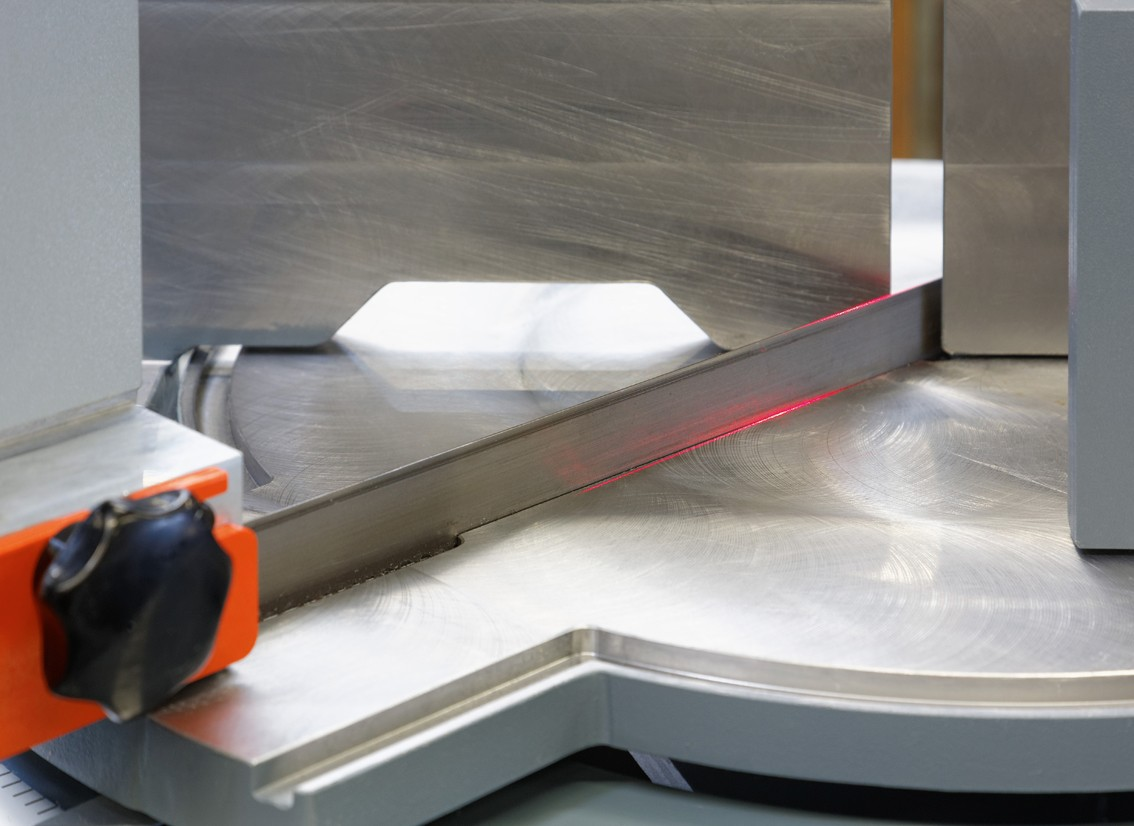

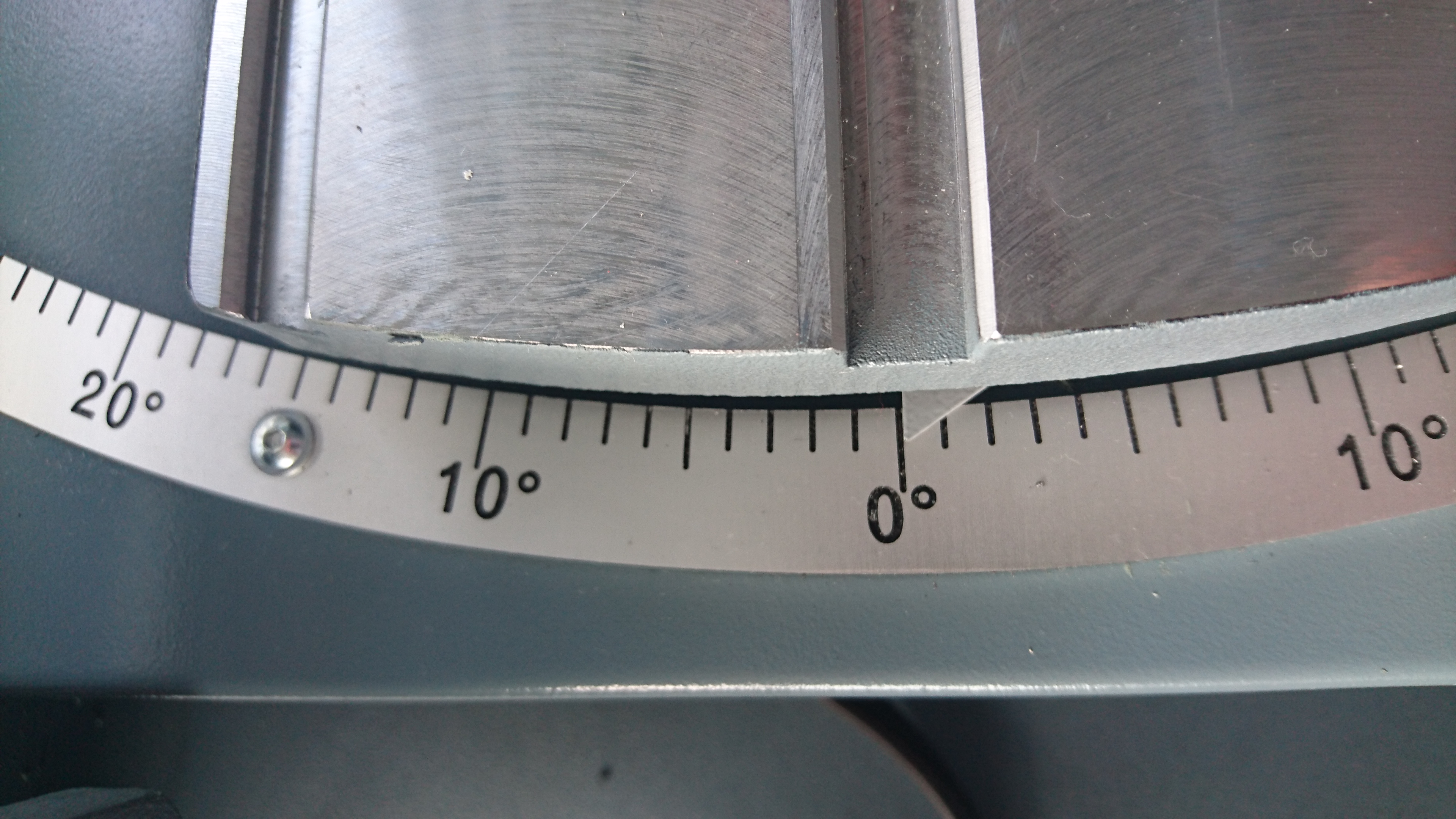

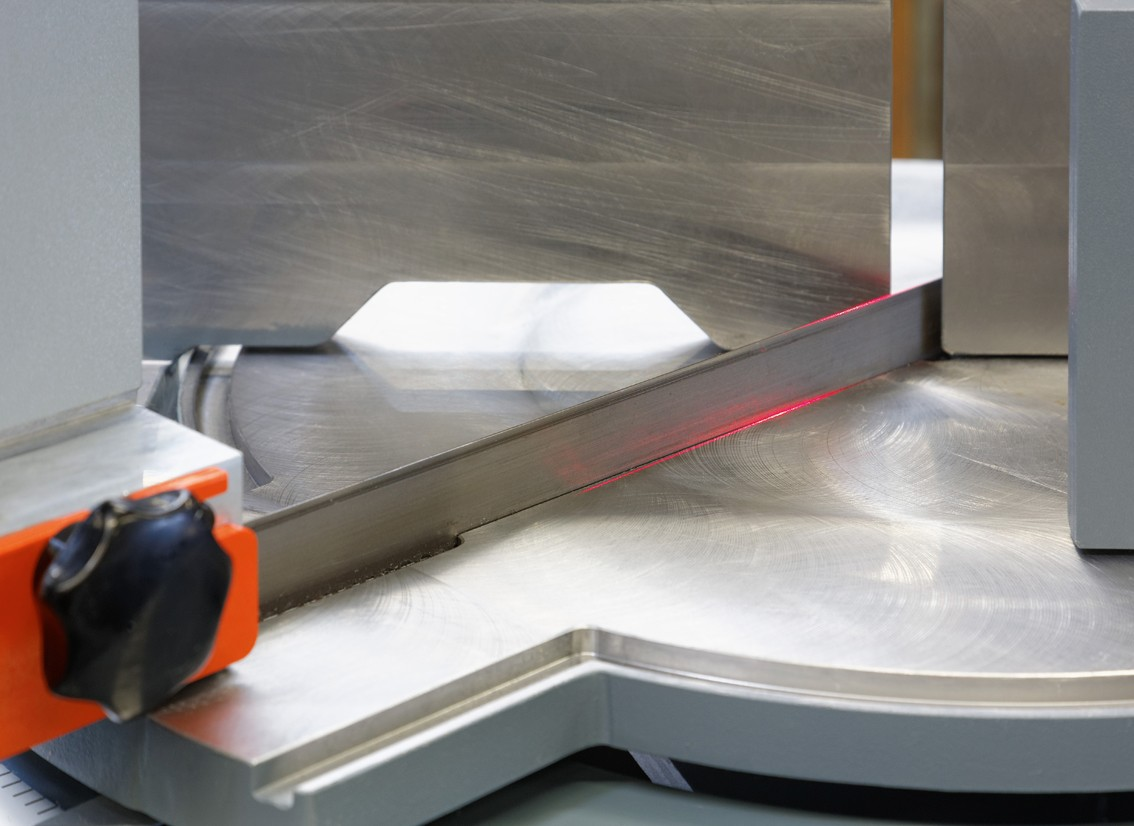

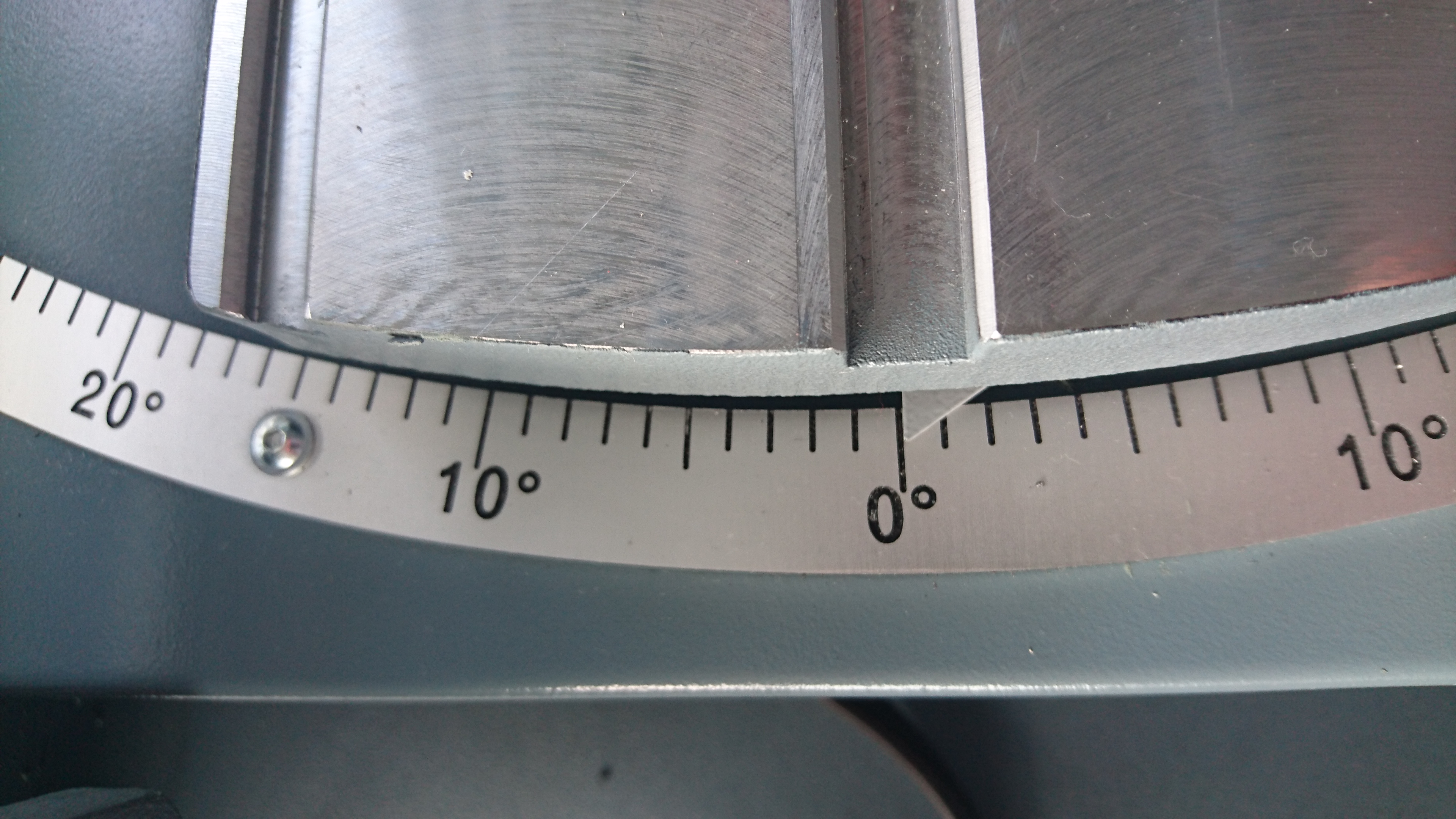

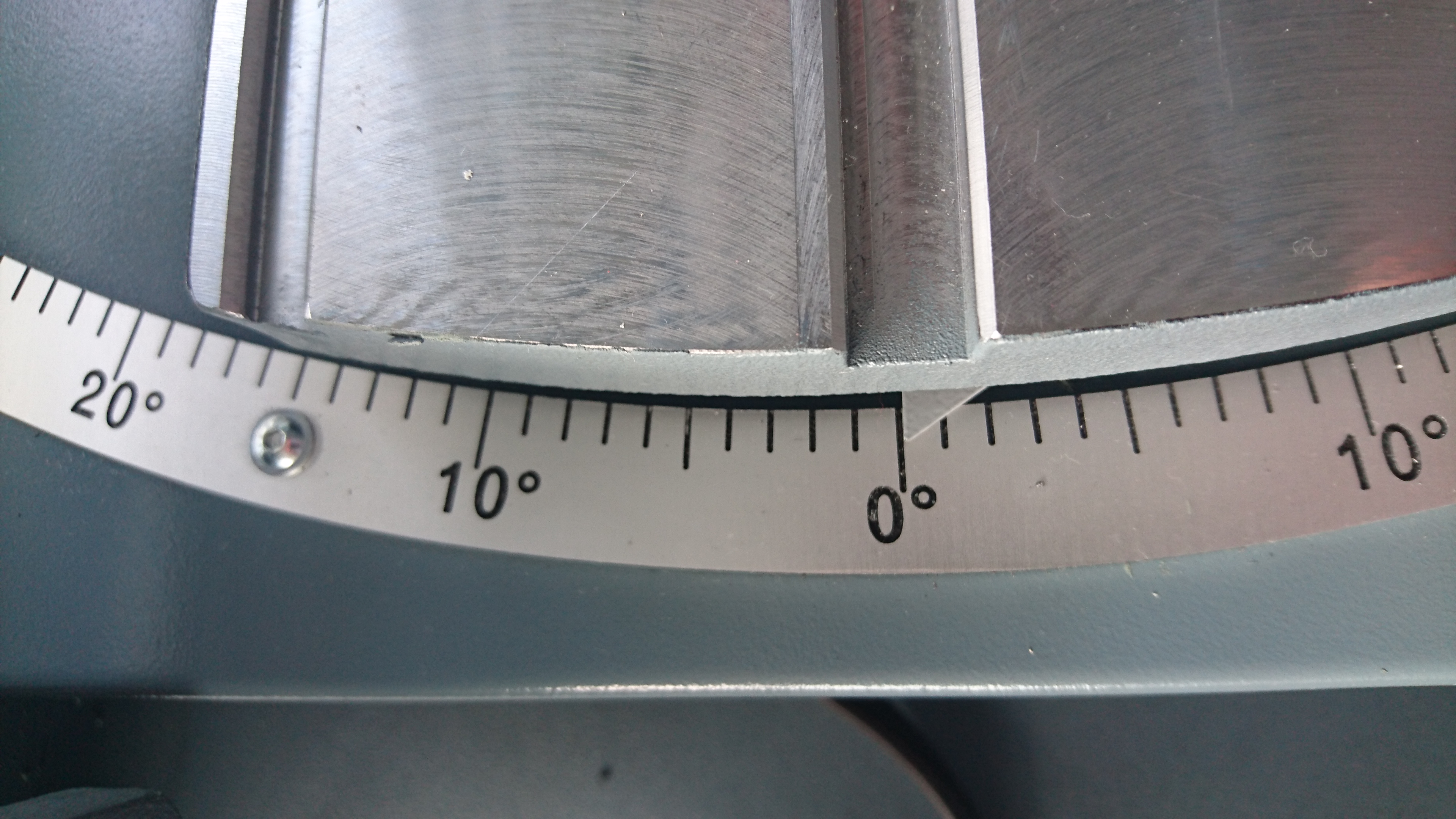

- Fast, stepless miter adjustment from 30° to 150° with 0.5° accuracy via scale. The miter pivot point is the intersection between the saw blade and the material support, ensuring no change in length

- Central machine operation

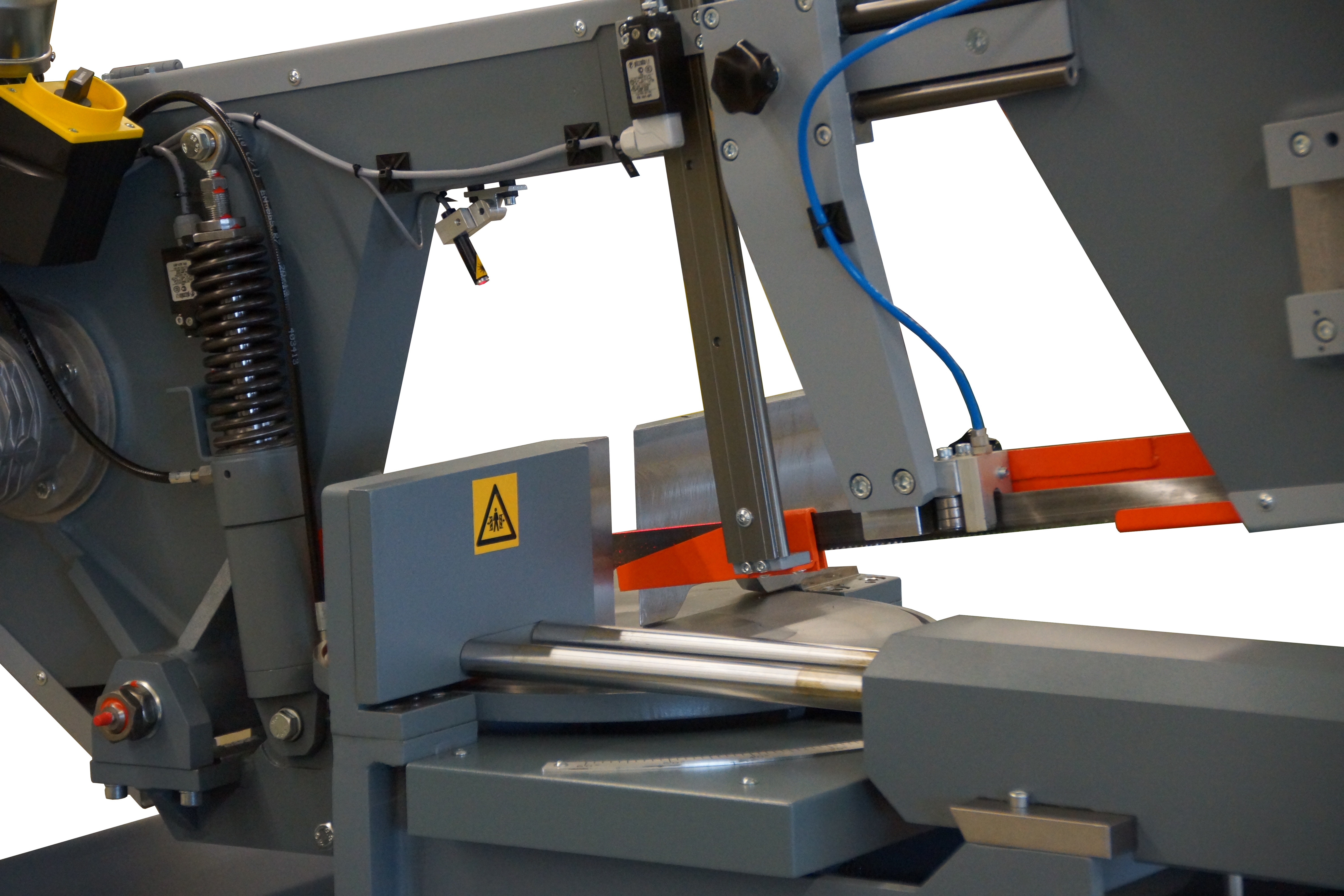

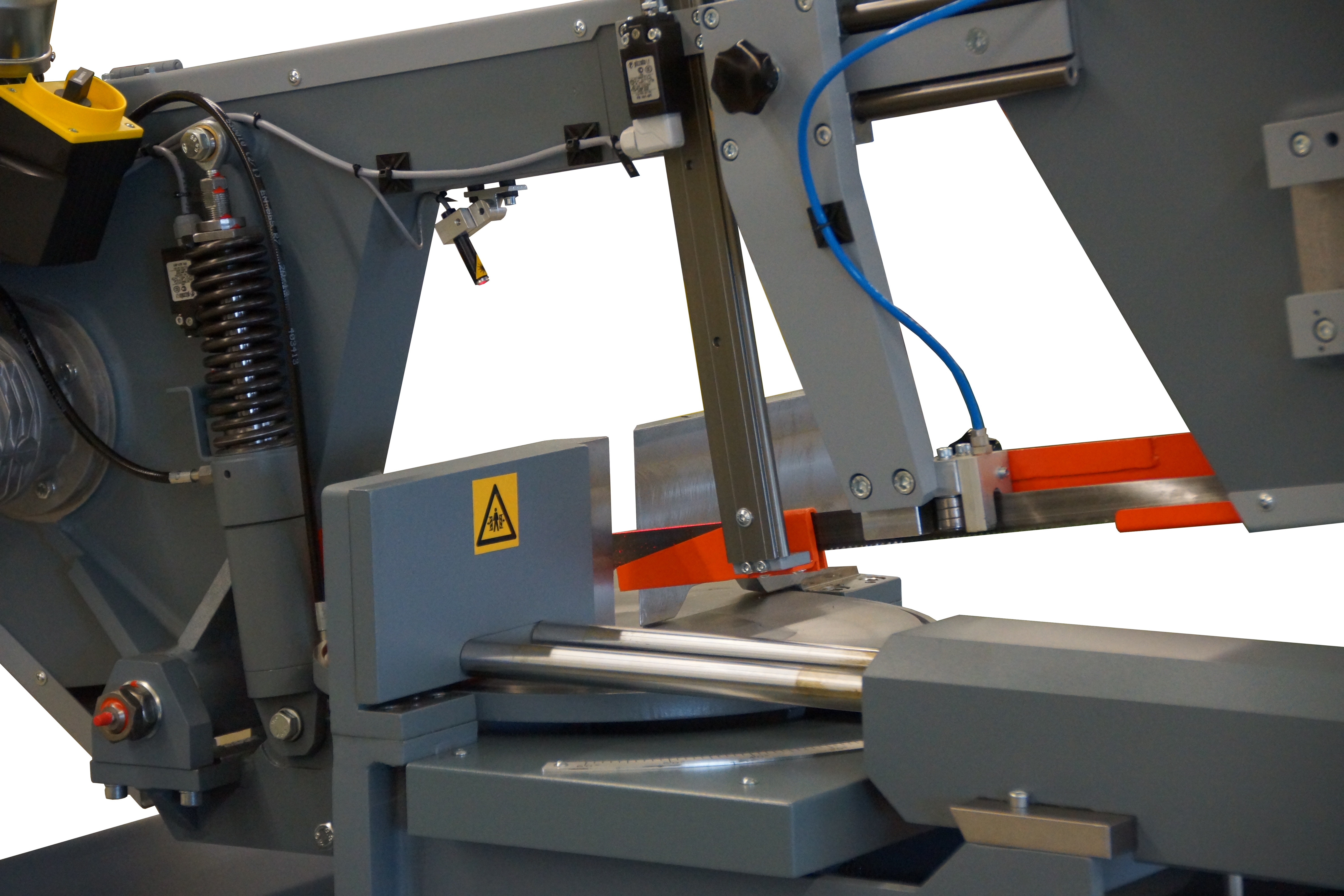

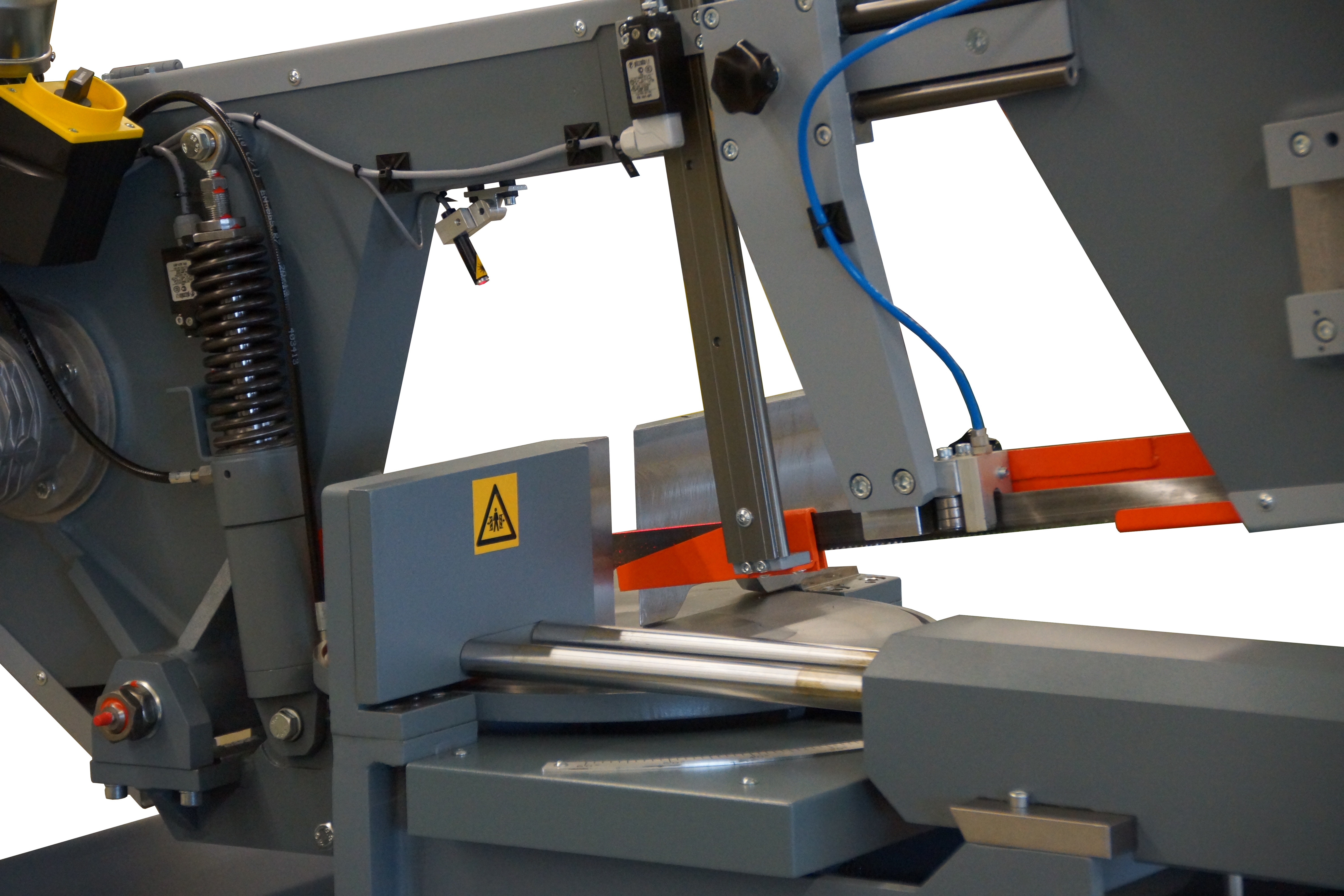

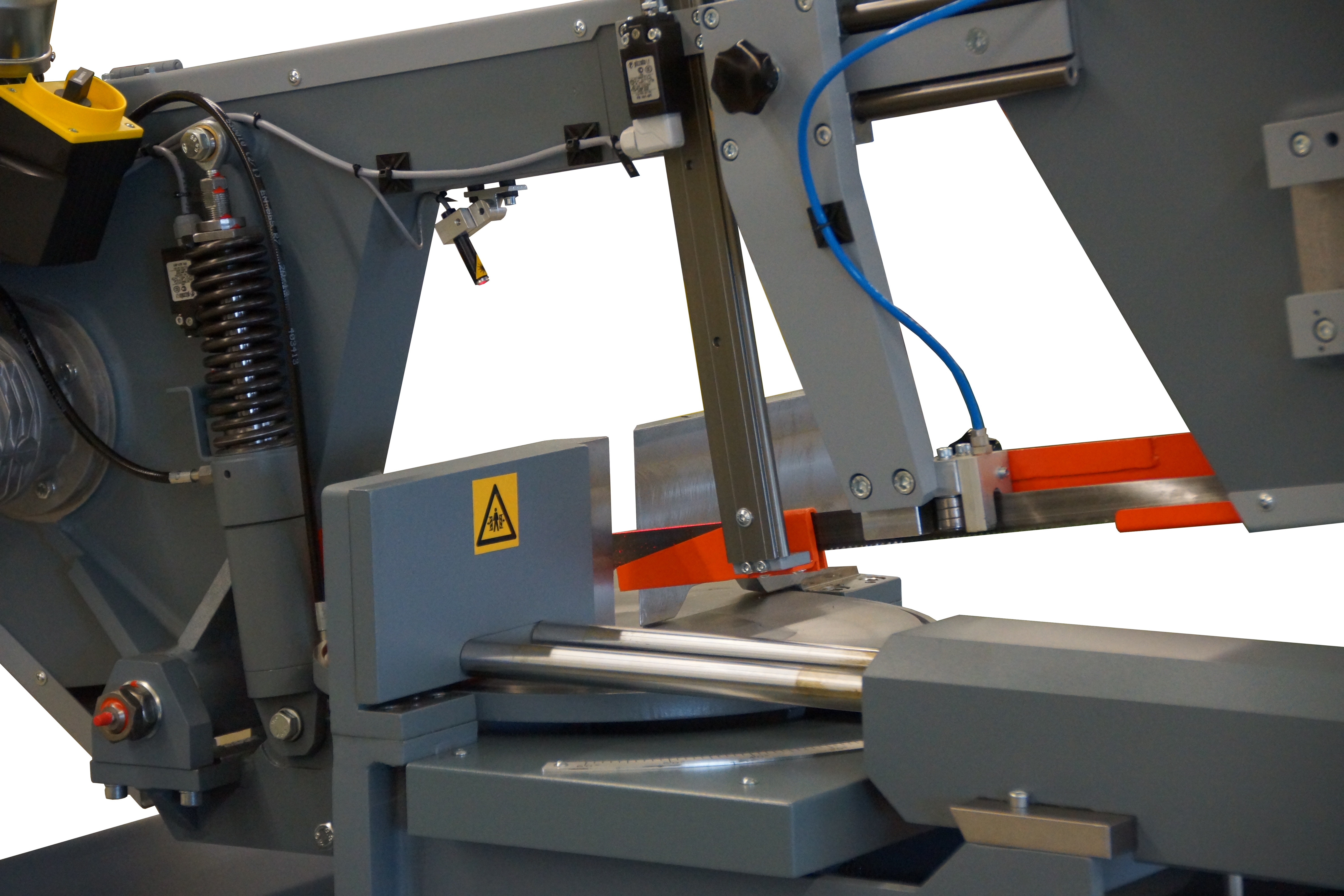

- Manual material clamping; at any saw frame angle, the material is clamped square to the material support edge

- Cutting pressure reduction by the dead weight of the heavy, torsion-resistant saw frame, with fine adjustment via hydraulic damping cylinder depending on material cross-section

- Saw blade drive with automatic shut-off

- Stepless clamping jaw adjustment

- Movable band guide arm, adjustable to material width

- Standard coolant system, optionally expandable with a micro-dosing system

- Machine stand with chip collection tray

- Mechanical saw blade tension

- Precision carbide roller saw blade guidance

- Paint finish silver gray / blue gray (RAL 7001 / RAL 7031)

- Operating manual and spare parts list (digital)

- 1 saw blade mounted on the machine, 4/6 TPI

Optional

- Hydraulic lifting of the saw frame with check valve

-

Measuring stop 0–600 mm – right

-

Measuring stop 0–600 mm – left

-

Special 2-color paint finish according to RAL chart

-

Compressor for micro-dosing system

- Roller conveyors available in various lengths

Specifications subject to change without notice.

Specifications subject to change without notice. | Product number: | SWI_260DG00.0 |

|---|---|

| Automation level: | Single cut |

| Cutting material: | Pipe, Round Stock Material, Round solid material, Square solid material |

| Cutting speed: | 35 + 75 m/min |

| Dimensions: | 800x1720x1450 mm |

| Max. cutting range height ↕ (mm): | 260 |

| Max. cutting range width ↔ (mm): | 300 |

| Max. cutting range Ø (mm): | 230 |

| Remaining piece length: | 25 mm |

| Saw blade dimensions: | 3350x27x0,9 mm |

| Saw blade drive: | 1,1/1,8 kW |

| Saw blade tension: | Mechanical |

| Type: | Double Mitre Saw 30°-150° |

| Type series: | MEBAswing |

| Weight: | 710 KG |

| Working height: | 900 mm |

| version: | Standard Machine, With Laser Light, With Micro Dispensing Unit & Laser Light, With Microdosing Unit |

0 of 0 reviews

Login

No reviews found. Share your insights with others.

Fitting parts

O-335027114

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-335027508

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-335027406

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-335027203

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

O-335027304

The Allround + saw blade impresses with its high cutting accuracy and wear resistance thanks to an alloyed high-speed steel. The advantage here is a long service life for sawing work that is susceptible to vibrationApplication area: For thin-walled material and wall thicknesses, small workpiece dimensions, profiles with thin or medium

workpiece dimensions, profiles with thin or medium wall thicknesses,

short-chip materials up to medium to large workpiece

workpiece dimensions, steels and non-ferrous metals, materials with

tensile strengths of up to 1,400 N/mm², thick-walled profiles as well as pipes and beams.

For example: Structural steel, deep-drawing steel and free-cutting steel

Material: M42

Tooth shape: Normal

A real "all-rounder".

OS335027507

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OS335027304

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OS335027406

The Profile + band saw blade impresses with

improved belt service life due to the resistant, impact-resistant tooth edge and

tooth edge and optimized resistance to increased abrasion conditions and cutting temperatures.

abrasion conditions and cutting temperatures.

Application area: Small and medium material and wall thicknesses

wall thicknesses, steel beams, profiles, pipes, workpiece mix, sawing bundles

OX335027304

The Performance + band saw blade impresses with its tooth profile

for easier sawing with reduced feed rates. It withstands higher cutting temperatures and downforce, giving it extremely high wear resistance.

wear resistance.Field of application: DThick-walled profiles, steels and non-ferrous metals, materials

with tensile strengths of up to 1,400 N/mm², stainless and acid-resistant steels,

high feed rates, shortened sawing timese.g: Structural steel, deep-drawing steel, free-cutting steel, ball bearings

and unalloyed tool steel. Aluminum, copper and brass,

High-speed steel and cold work steel. Nitriding steel, stainless and

acid-resistant steels. TitaniumMaterial: M42Tooth shape: Normal

For customers who value a long service life and shorter sawing times.

sawing times.

OX335027203

The Performance + band saw blade impresses with its tooth profile

for easier sawing with reduced feed rates. It withstands higher cutting temperatures and downforce, giving it extremely high wear resistance.

wear resistance.Field of application: DThick-walled profiles, steels and non-ferrous metals, materials

with tensile strengths of up to 1,400 N/mm², stainless and acid-resistant steels,

high feed rates, shortened sawing timese.g: Structural steel, deep-drawing steel, free-cutting steel, ball bearings

and unalloyed tool steel. Aluminum, copper and brass,

High-speed steel and cold work steel. Nitriding steel, stainless and

acid-resistant steels. TitaniumMaterial: M42Tooth shape: Normal

For customers who value a long service life and shorter sawing times.

sawing times.

OX335027406

The Performance + band saw blade impresses with its tooth profile

for easier sawing with reduced feed rates. It withstands higher cutting temperatures and downforce, giving it extremely high wear resistance.

wear resistance.Field of application: DThick-walled profiles, steels and non-ferrous metals, materials

with tensile strengths of up to 1,400 N/mm², stainless and acid-resistant steels,

high feed rates, shortened sawing timese.g: Structural steel, deep-drawing steel, free-cutting steel, ball bearings

and unalloyed tool steel. Aluminum, copper and brass,

High-speed steel and cold work steel. Nitriding steel, stainless and

acid-resistant steels. TitaniumMaterial: M42Tooth shape: Normal

For customers who value a long service life and shorter sawing times.

sawing times.

OD335027406

The material + saw blade impresses with its precision

due to the ground positive rake angle and ground tooth gaps.

This reduces the cutting force at higher cutting speeds.

is reduced. Due to the cutting accuracy, it has a high load capacity in terms of

duration, heat and wear.

Field of application: FFor demanding cutting conditions, materials with tensile strengths of up to 1,700 N/mm².

tensile strengths of up to 1,700 N/mm², high-alloy materials, bronzes,

titanium alloyse.g.: rust- and acid-resistant steels,

Nickel-based alloysMaterial: M51Tooth shape: Normal

The Material+ has an aggressive tooth geometry

- which, in conjunction with the harder cutting edge material M51, is suitable for particularly

is suitable for particularly demanding materials.

OD335027203

The material + saw blade impresses with its precision

due to the ground positive rake angle and ground tooth gaps.

This reduces the cutting force at higher cutting speeds.

is reduced. Due to the cutting accuracy, it has a high load capacity in terms of

duration, heat and wear.

Field of application: FFor demanding cutting conditions, materials with tensile strengths of up to 1,700 N/mm².

tensile strengths of up to 1,700 N/mm², high-alloy materials, bronzes,

titanium alloyse.g.: rust- and acid-resistant steels,

Nickel-based alloysMaterial: M51Tooth shape: Normal

The Material+ has an aggressive tooth geometry

- which, in conjunction with the harder cutting edge material M51, is suitable for particularly

is suitable for particularly demanding materials.

OD335027304

The material + saw blade impresses with its precision

due to the ground positive rake angle and ground tooth gaps.

This reduces the cutting force at higher cutting speeds.

is reduced. Due to the cutting accuracy, it has a high load capacity in terms of

duration, heat and wear.

Field of application: FFor demanding cutting conditions, materials with tensile strengths of up to 1,700 N/mm².

tensile strengths of up to 1,700 N/mm², high-alloy materials, bronzes,

titanium alloyse.g.: rust- and acid-resistant steels,

Nickel-based alloysMaterial: M51Tooth shape: Normal

The Material+ has an aggressive tooth geometry

- which, in conjunction with the harder cutting edge material M51, is suitable for particularly

is suitable for particularly demanding materials.

SWI BK0000X

Additional package consisting of 6x hard metals and 12x deflection bearings

V ML0100000M

Measuring stop with scale, free travel device incl. guide rail

Tip

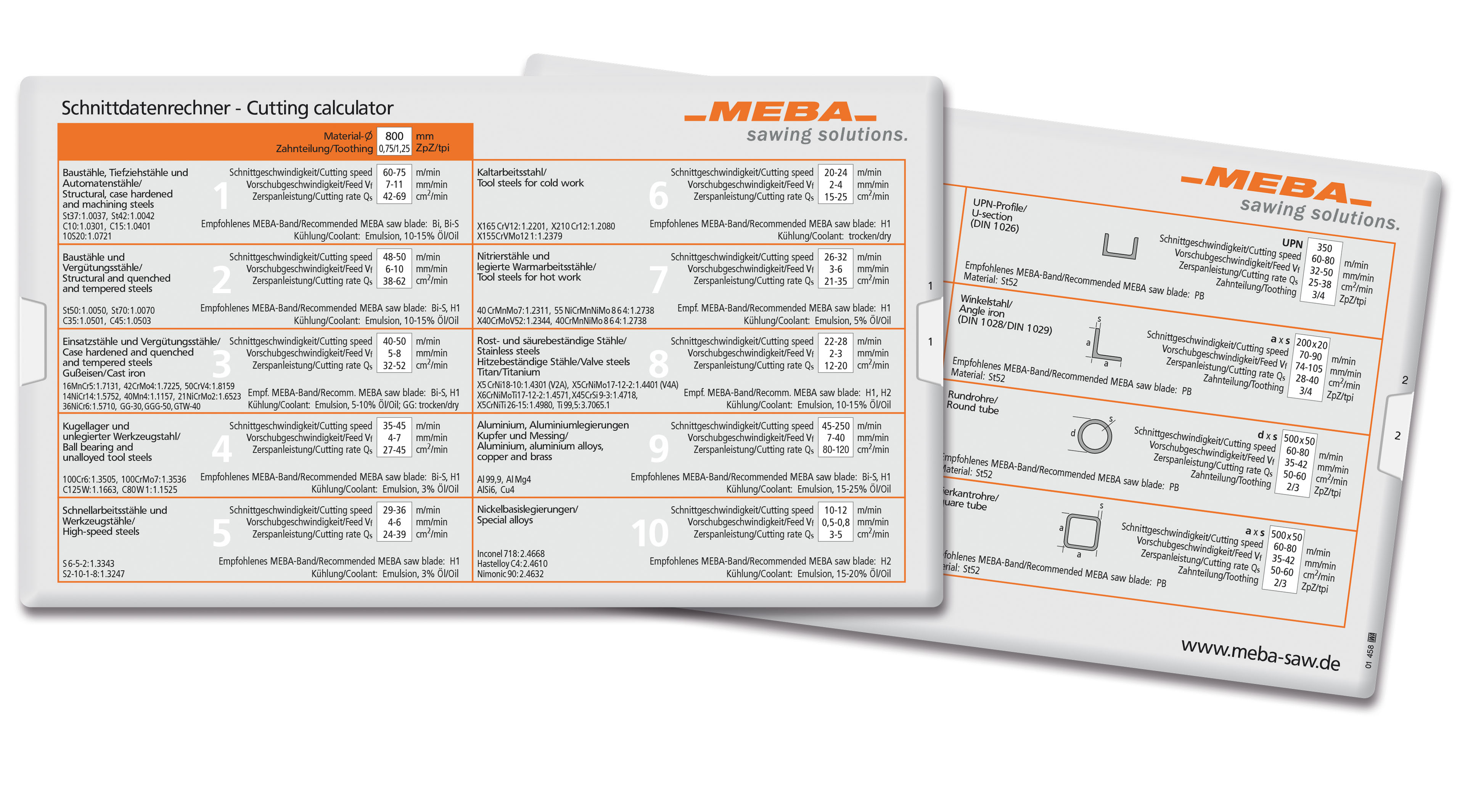

W SCHNITTDA

Individual recommendation for cutting speed, feed rate, cutting performance and tooth pitch of the band saw blade.

V MLD100000M

Manual, digital measuring stop, linear guided