Ball bearing

Ball bearings

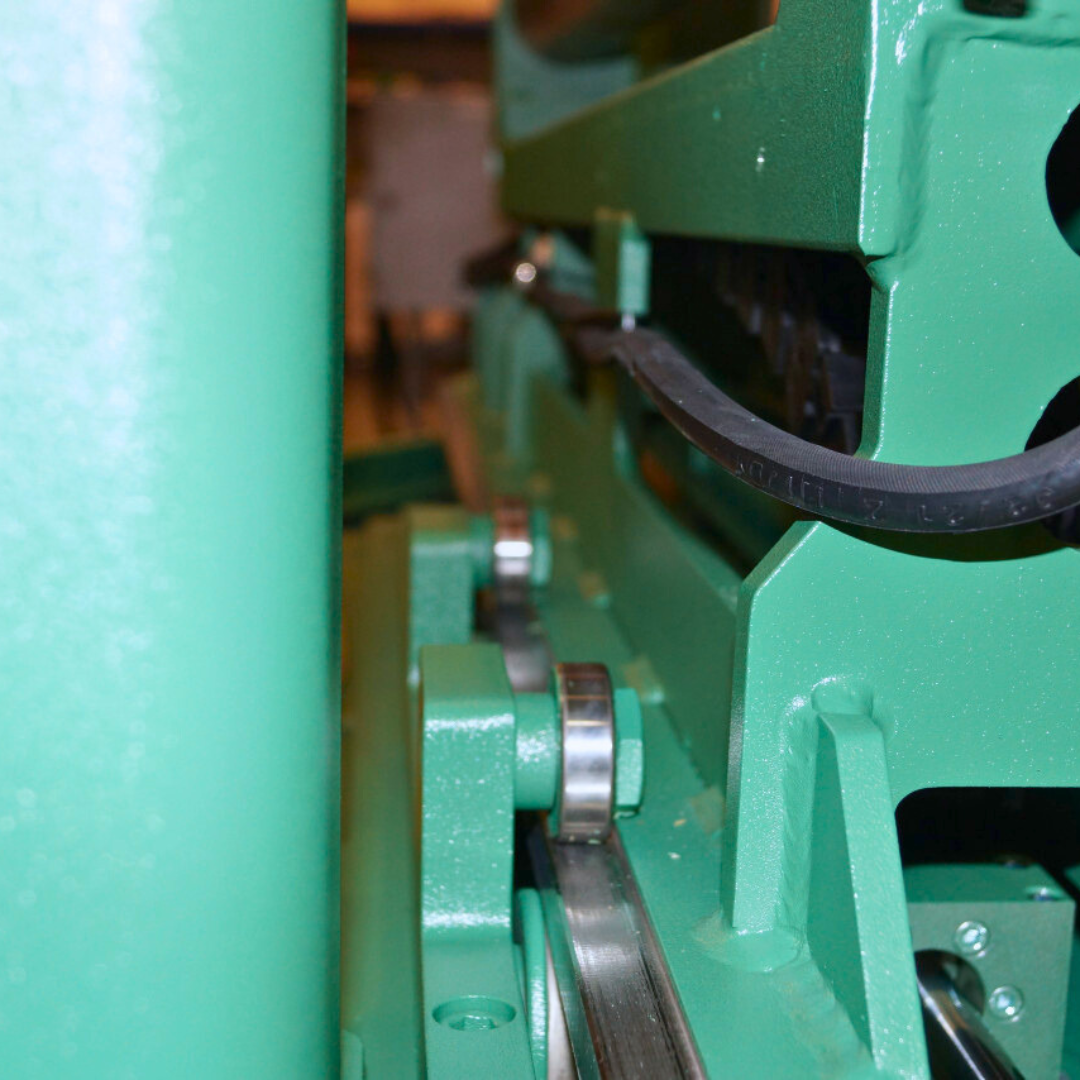

Our high-quality deep groove ball bearing, weighing 0.3 kg, is compatible with machine types pro300A, mat330, eco335, eco410, and eco510. It ensures smooth and reliable movement of your machine components and contributes to the longevity and efficiency of your saws.

✔ Precision manufacturing for minimal running resistance

✔ High load capacity for long-term use

✔ Compatible with multiple MEBA machine types

Vertrauen Sie auf Qualität und Stabilität – für optimale Leistung Ihrer Maschinen.

| Product number: | 00625-06200 |

|---|---|

| Brush Set bandsaw blade: | For 34mm bandsaw blade, For 41mm bandsaw blade |

| Color: | black, grey |

| Machine type: | MEBAeco 335 90°, MEBAeco 410 90°, MEBAeco 510 90°, MEBApro 300 A, MEBAeco 335 (G, DG, DGA), MEBAeco 410 (A, DG, DGA), MEBAeco 510 (A, DG, DGA), MEBAmat 330, MEBAmat 434, 435, MEBAsteel 1100 (DG, DGA), MEBAsteel 1250 DG, MEBAxtreme 800, MEBAxtreme 1000-1000 / 1250-1000, MEBAxtreme 1140-510 / 1250-510 |

| Weight: | 0,3 KG |

| surface: | glossy |

Login