MEBAPro 300A

MEBApro: Your entry into automation

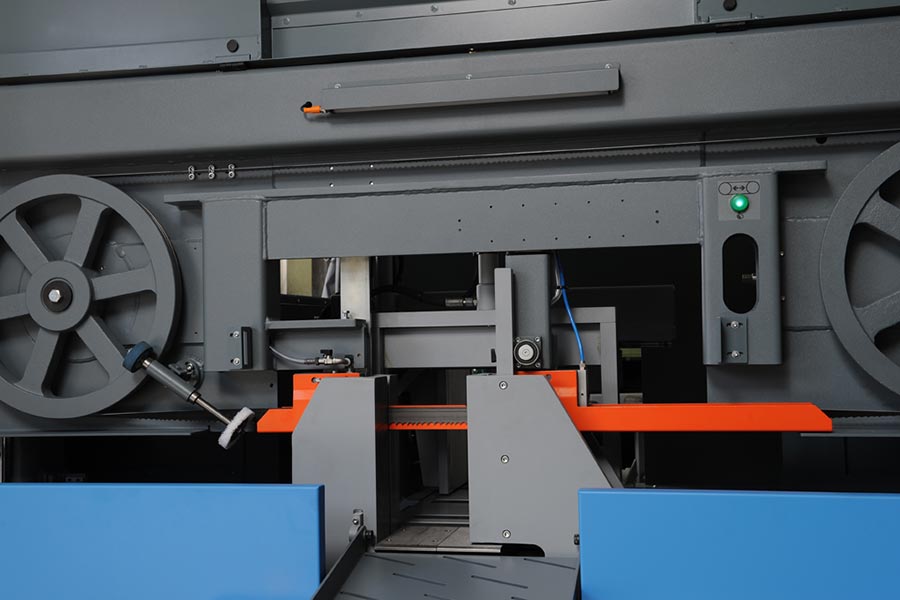

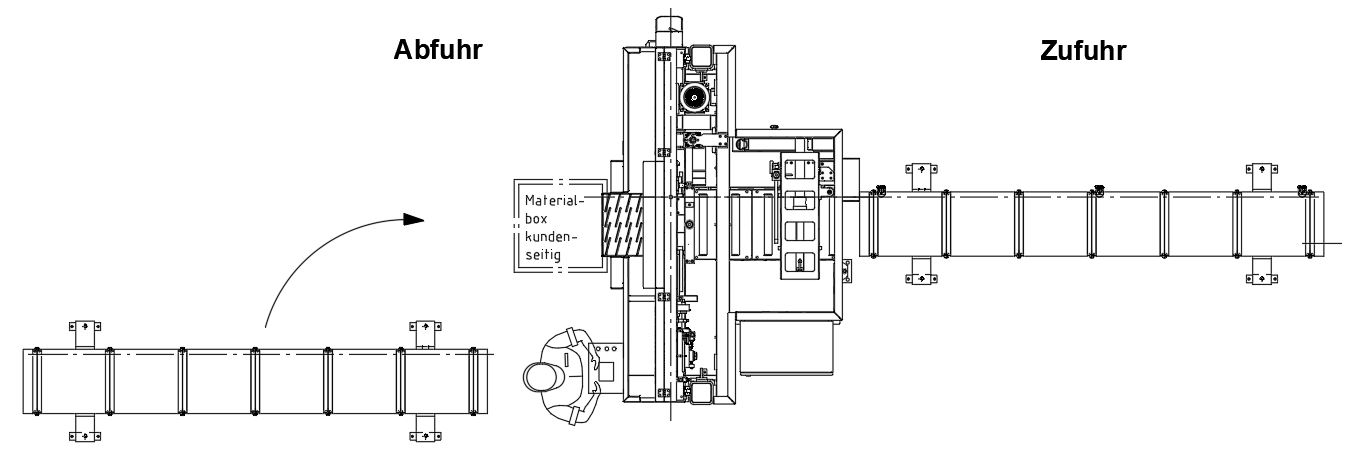

The 90° automatic saw for single and series cuts and workpiece dimensions up to 300x300 mm or 300 mm diameter combines high performance with automation. The compact design requires little space. The saw can be set up flexibly. High performance and cutting quality promise increased productivity. Easy to commission. Easy to operate thanks to a large display and simple menu navigation.

Standard equipment

- The machine base of the MEBApro 300 A is torsion-resistant and ensures high stability and quality.

- The closed and continuous base surface facilitates cleaning and reduces chip accumulation.

- The hydraulics are protected inside the machine base while remaining easily accessible.

- Integrated leveling feet are included as standard.

- Lashing eyes and easily accessible forklift pockets ensure safe transport; the forklift pockets are covered.

- The machine enclosure meets CE standards, providing a clean and safe working environment.

- The large wheel cover opens upwards with gas spring assistance, allowing easy access for saw band changes and cleaning.

- A safety tunnel with integrated splash guards and protective plates ensures clean and safe operation.

- Oversized inspection openings provide excellent access for service and maintenance.

- The control cabinet is protected and mounted on the machine base.

- The saw frame consists of a torsion-resistant welded structure analyzed by FEM, ensuring smooth, vibration-free cutting.

- The saw frame guide is precise, with an external double-portal construction combined with linear and ball screw technology.

- The saw band guides can be easily opened during band changes.

- The lateral band guide consists of pre-tensioned carbide sliding guides and band twist rollers.

- High cutting forces are achieved through roller-back guides, which also increase saw band service life.

- A secure, integrated water supply ensures optimal cooling during cutting.

- The saw feed is driven by an AC motor with electrically frequency-controlled ball screw.

-

The saw feed speed is infinitely adjustable from 0 to 600 mm/min.

-

Continuous monitoring of cutting pressure and feed ensures process reliability and automatic feed speed adjustment.

-

Saw band tension is electrically monitored, kept constant via a spring package, and adjusted with standard tools.

-

The cast steel guide ensures precise saw band tension and constant force transmission; the band run is adjustable.

-

Automatic band break monitoring provides process safety and shuts down the machine in case of band break.

-

The saw band is cleaned by a driven round brush synchronized to the saw band speed; the brush unit is removable for saw band changes.

-

The clamping system operates with hydraulic full stroke, linear ball guides, and an integrated material end sensor.

-

The infeed clamping vice opens on both sides; the fixed jaw is liftable from the zero edge, and the double clamping vice ensures burr-free cutting.

-

The machine roller conveyor uses six ball-bearing support rollers, is cantilevered, and can handle material up to 250 kg/m.

-

The material lift device raises the material after cutting, extending saw band life.

-

The saw motor delivers 3 kW, is infinitely adjustable from 15 to 130 m/min, the coolant system has a capacity of approx. 100 liters, is integrated into the machine base, features a dual filter system, and includes a modem for remote access.

-

Laser light for cut line indication / scribing saws

-

Micro-dosing system

-

Clamping pressure regulation at the control panel

-

LED work light

-

7" CE panel MEBApro 300 A

-

Material bundle clamping, hydraulic

-

Zero stop

-

Screw-type chip conveyor

-

Mobile chip tipping container for forklift transport

-

Vertical roller

-

Special two-color paint finish according to RAL chart

-

Compressor for micro-dosing system

-

MEBApro water spray gun

-

Coolant heater

-

Hydraulic unit heater

- MEBA NC Server: external postprocessor

- Roller conveyors available in various lengths

Specifications subject to change without notice.

Specifications subject to change without notice.| Product number: | PRO 300A020 |

|---|---|

| Automation level: | Serial cut |

| Cutting material: | Pipe, Round Stock Material |

| Cutting speed: | 15 - 130 m/min |

| Dimensions: | 1650x2500x1800 mm |

| Max. cutting range height ↕ (mm): | 300 |

| Max. cutting range width ↔ (mm): | 300 |

| Max. cutting range Ø (mm): | 300 |

| Remaining piece length: | 20 mm |

| Saw blade dimensions: | 4900x34x1,1 mm |

| Saw blade drive: | 3,0 kW |

| Saw blade tension: | Hydraulic |

| Type: | Miter Saw 90° |

| Type series: | MEBApro |

| Weight: | 2500 KG |

| Working height: | 750 mm |

Login