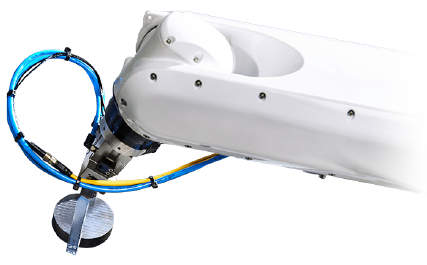

MEBA robot Nachi MC 70

MEBArobots – Automation that works

MEBArobots automate sawing processes – reliably, economically, and practically. From entry-level automation to fully integrated solutions: MEBArobots are designed for 24/7 operation and can be adapted to any size of business.The 6-axis industrial robots operate flexibly with a repeat accuracy of up to 0.02 mm. They master precise handling, post-processing, and quality control tasks. The close integration of the saw, robot, and control system automates work steps—consistently, reliably, and without downtime.The result: higher productivity, lower costs, and more freedom for qualified specialists. Saving just one employee can pay for the investment within a year.

Technical highlights

- 6 axes for maximum flexibility

- Load capacity: 70 kg

- Reach: 2050 mm

Accessories

- Schunk universal gripper PGN-plus-P

Universal 2-finger parallel gripper for secure handling tasks, max. workpiece weight approx. 5 kg - Fingers for parallel gripper

Adapted to pick-up and deposit situations, e.g. for diameters of approx. 80–105 mm and section lengths of approx. 30–50 mm - Programming for the application

Creation of a robot program adapted to the pick-up and deposit situation, optionally with intermediate station (deposit station, material cleaning) - Console for floor mounting

Console for precise positioning and fastening of the robot, taking into account the pick-up and deposit situation - Cleaning station

Deburring unit for components up to Ø 105 mm - Material storage

Adapted to the respective deposit situation - Machine modifications

Mechanical and technical adaptations to enable part removal by the robot - Access protection according to CE standard

Protective fence for standards-compliant safeguarding of the robot working area

| Product number: | V MR100410X |

|---|---|

| axis: | 6 |

| load capacity: | 70 kg |

| range: | 2050 mm |

Login