MEBAPro 260 AP

MEBApro: Your introduction to automation

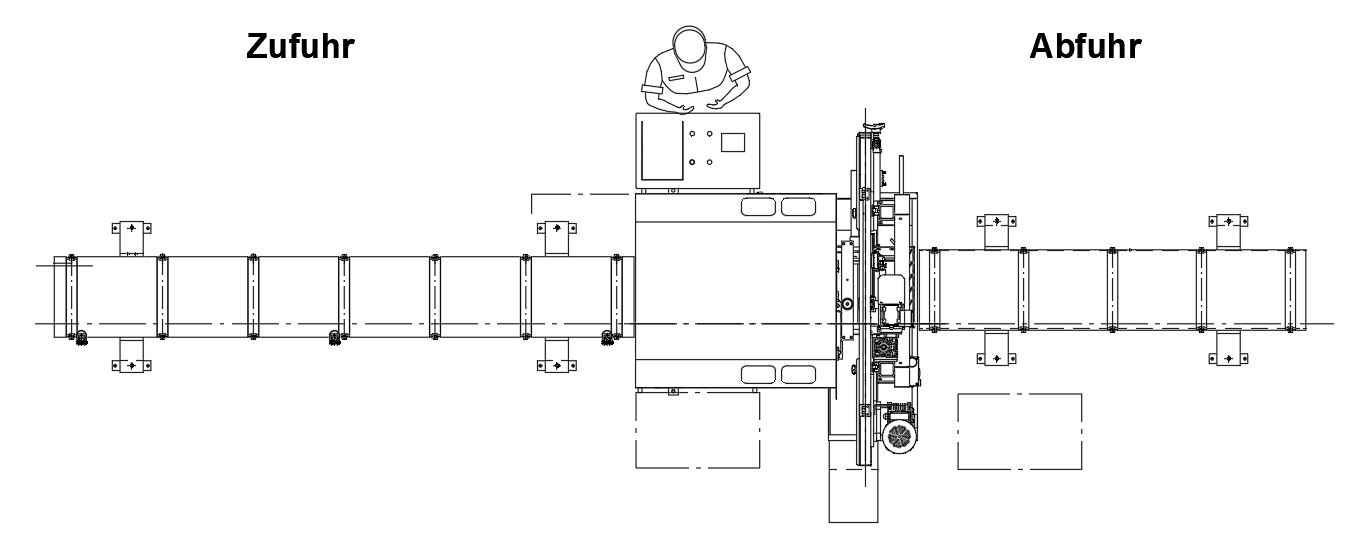

The 90° automatic machine for single and series cuts and workpiece dimensions up to 300x260mm or 260mm diameter combines high performance with automation. The compact design requires little space and can be set up flexibly. High performance and cutting quality promise increased productivity, and easy commissioning and operation are provided.

Standard equipment

- The PC is built to industrial standards, maintenance-free, fanless, and does not require a battery.

- The touchscreen is resistive and features a 4.3-inch color TFT display with a self-adhesive protective film and front-side protection.

- The machine is equipped with interfaces including 1× Ethernet (integrated switch), 1× USB master, and 1× EtherCAT.

- The operating system is Windows CE 6.0, and PLC control is based on IEC 61131-3 using CODESYS3.

- The machine supports fully automatic operation, 2,000 programmable data sets, and program management.

- A continuous bus network monitors the drives, controllers, and control system, enabling easy fault diagnosis.

- Menu navigation uses self-explanatory icons; language switching is possible online, and measurement units can be switched between metric and imperial.

- The position display supports service operations; current warnings and fault messages are highlighted in color, and all information is documented.

-

The machine is equipped with a total operating hours counter, a resettable operating hours counter for saw band service life and sawing time per job, as well as a total and resettable piece counter.

-

The automatic initial cut function automatically reduces cutting parameters for optimal band engagement.

-

The machine is prepared for digital services.

-

The saw frame consists of a torsion-resistant welded structure in double-portal design with recirculating ball guides and operates with low vibration.

-

Saw frame feed is driven by an AC motor with electronic frequency control, infinitely adjustable from 0 to 600 mm/min, and automatically calculates the cut-through point.

-

The saw band guides consist of carbide sliding guides and band twist rollers, operating precisely while protecting the band.

-

Saw band tensioning is achieved via a spring package with handwheel; a robust steel cast guide ensures constant force, and the machine includes band break monitoring and automatic shutdown.

-

The saw motor delivers 1.5 kW, is infinitely adjustable from 15 to 150 m/min, and is energy-efficient.

-

The clamping system operates hydraulically with full stroke, linear ball guides, an integrated material end sensor, a removable infeed clamping vice, and jaws that open on both sides.

-

The machine base is torsion-resistant and features a closed base surface; the hydraulics are protected, and lashing eyes as well as forklift pockets are integrated.

-

The machine roller conveyor uses ball-bearing precision rollers, includes five support rollers, and supports material up to 250 kg/m with a maximum length of 3 m.

-

The cut-off chute is inclined, features integrated coolant return, and is suitable for box disposal.

-

The material lift-off device raises the material after cutting, thereby extending saw band service life.

- The coolant system has a 140-liter tank, is integrated into the machine base, and is easy to remove.

-

The hydraulic system operates with a 1.1 kW power unit, is energy-efficient thanks to a pressure accumulator, integrated into the machine base, and easily accessible for maintenance.

-

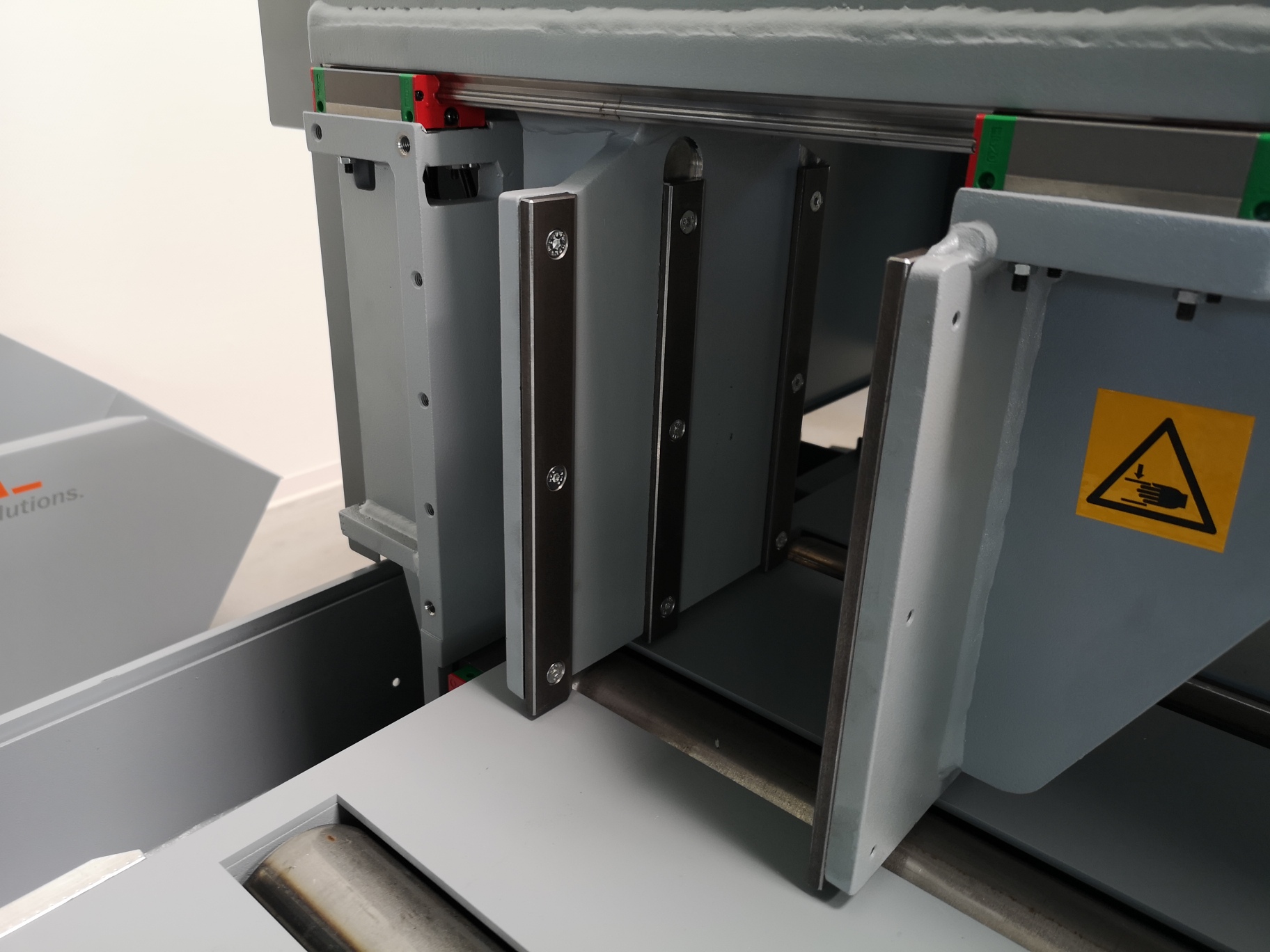

The machine enclosure is CE-compliant, features a large hinged cover for saw band changes and cleaning, and includes a modem for remote access.

-

Laser light for cut line indication / scribing saws

-

Micro-dosing system

-

Clamping pressure regulation at the control panel 260 AP

-

Control panel installed separately

-

Clamping pressure regulation with separately installed control panel

-

Material bundle clamping, hydraulic, full stroke

-

Zero stop (automatic zero positioning)

-

Scraper belt conveyor for optimal chip disposal

-

Mobile chip tipping container for forklift transport

-

Water spray gun

-

Heater for hydraulic power unit

-

Special two-color paint finish according to RAL chart

-

Compressor for micro-dosing system

-

Leveling elements (4 pieces)

-

Adjustable deflector plate

- Driven chip brush, Ø 85 mm

- Signal light with three-color status indication

-

Chip drawer

-

Control panel permanently mounted on the fixed-jaw side

-

Set of serrated clamping strips 260 AP

-

7" CE panel MEBApro 260 AP

-

Cut progression monitoring 260 AP

-

USB interface

-

MEBA NC Server: external postprocessor

-

Data exchange via OPC UA for P300 incl. 10 m patch cable

- Roller conveyors available in various lengths

Specifications subject to change without notice.

Specifications subject to change without notice.| Product number: | 260 AP000F1 |

|---|---|

| Automation level: | Serial cut |

| Cutting material: | Pipe, Round Stock Material |

| Cutting speed: | 15 - 150 m/min |

| Dimensions: | 1500x1800x1850 mm |

| Max. cutting range height ↕ (mm): | 260 |

| Max. cutting range width ↔ (mm): | 300 |

| Max. cutting range Ø (mm): | 260 |

| Remaining piece length: | 20 mm |

| Saw blade dimensions: | 3700x27x0,9 mm |

| Saw blade drive: | 1,5 kW |

| Saw blade tension: | Mechanical |

| Type: | Miter Saw 90° |

| Type series: | MEBApro |

| Weight: | 1050 KG |

| Working height: | 750 mm |

Login

17 July 2025 13:17

Wir sind sehr zufrieden

Die Säge läuft seit 4 Wochen bei uns. Top Beratung und Säge läuft bis jetzt einwandfrei.