MEBAmat 435

MEBAmat: The powerhouse for efficient production use

For a wide range of sawing tasks and maximum productivity: The high-performance automatic saw for even larger dimensions cuts everything from soft to extremely hard materials with all tool types, from bimetal to carbide. Fully networked and automated workflows minimize overhead costs and require minimal personnel – ideal for continuous operation in single- or multi-shift use. The enclosed design ensures safe and clean operation.

Standard equipment

- Machine stand: torsion-free welded construction for high stability

-

Optimized chip flow: angled support surfaces, easy to clean

-

Hydraulics: protected inside the machine stand but easily accessible

-

Leveling feet: standard; tie-down eyes and forklift pockets with covers included

-

Full enclosure: CE-compliant, quiet, safe working environment

-

Integrated control cabinet: protected from dirt and chips, easily accessible

-

Large swing doors & oversized service openings for maintenance

-

Plexiglass window for safe observation of the sawing process

-

Saw frame: double-portal frame, ball screw driven, low vibration, torsion-resistant

-

Saw blade guidance: hydraulically pre-tensioned, carbide sliding guides & hardened anti-twist rollers

-

Roller-guided band back: handles high cutting pressures and extends blade life

-

Automatic blade guidance adjustment according to material cross-section

-

Saw frame feed: servo drive via ball screw, stepless 0–600 mm/min

-

Permanent cutting pressure & feed monitoring: servo technology for dynamic sawing

-

Hydraulic saw blade tension: ensures constant tension, with blade break monitoring

-

Saw blade cleaning: modern double brush, synchronized to blade speed, self-adjusting

-

Material height adjustment: laser height & width detection, collision-proof

-

Clamp system: hydraulic, full-stroke cylinders, reversible clamping bars, linear ball-screw guides, material-end detection

-

Machine roller conveyor: load capacity up to 1200 kg/m, precision ball-bearing rollers, easily replaceable

-

Material lift device: raises material after cutting to protect the saw blade

-

Cut-off chute: angled, integrated coolant return, optional support table

- Saw motor: 5.5 kW, stepless 15–150 m/min, double-sided stable bearings

- Coolant system: 160 l tank, filter screen, 90 l/min pump at 3 m lift, easily removable

- Hydraulic unit: 1.1 kW, energy-saving, integrated in machine stand

-

Operation & control: touchscreen, bus networking, Windows CE, remote maintenance & modem

-

Zero stop with automatic program start

-

Material database

-

Clamping pressure regulation

-

Clamping pressure regulation < 5000 N

-

Swivel control panel – flexibly mountable

-

Job menu

-

Multi-bar clamping / layer clamping

-

Cut progress monitoring

-

Micro-dosing system

-

Compressor for micro-dosing system

- LED work light

-

Work table on the outfeed side

-

Water spray gun MEBAmat 3/8"

-

Laser pointer for cut line marking / layout cuts

-

Vertical roller

-

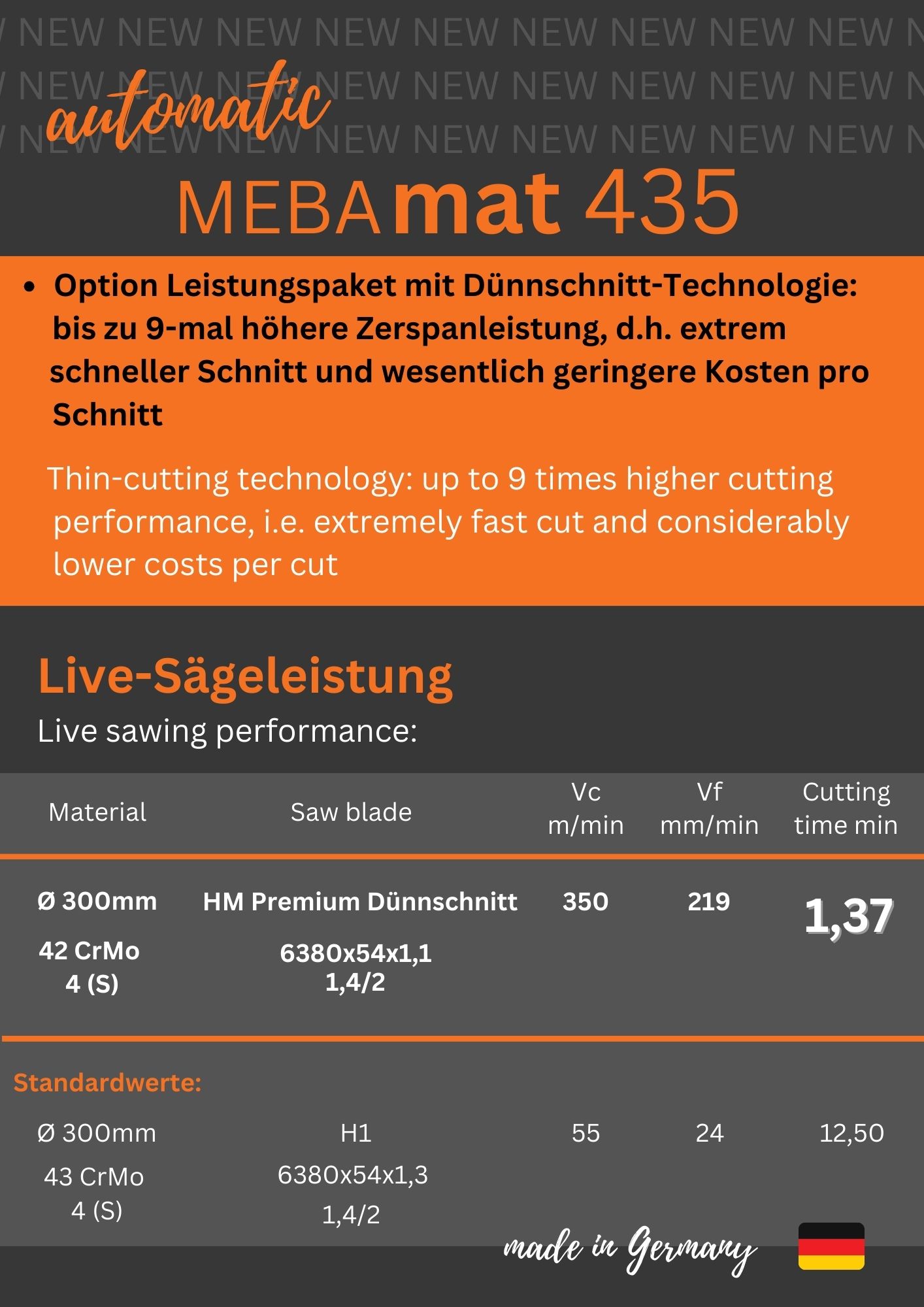

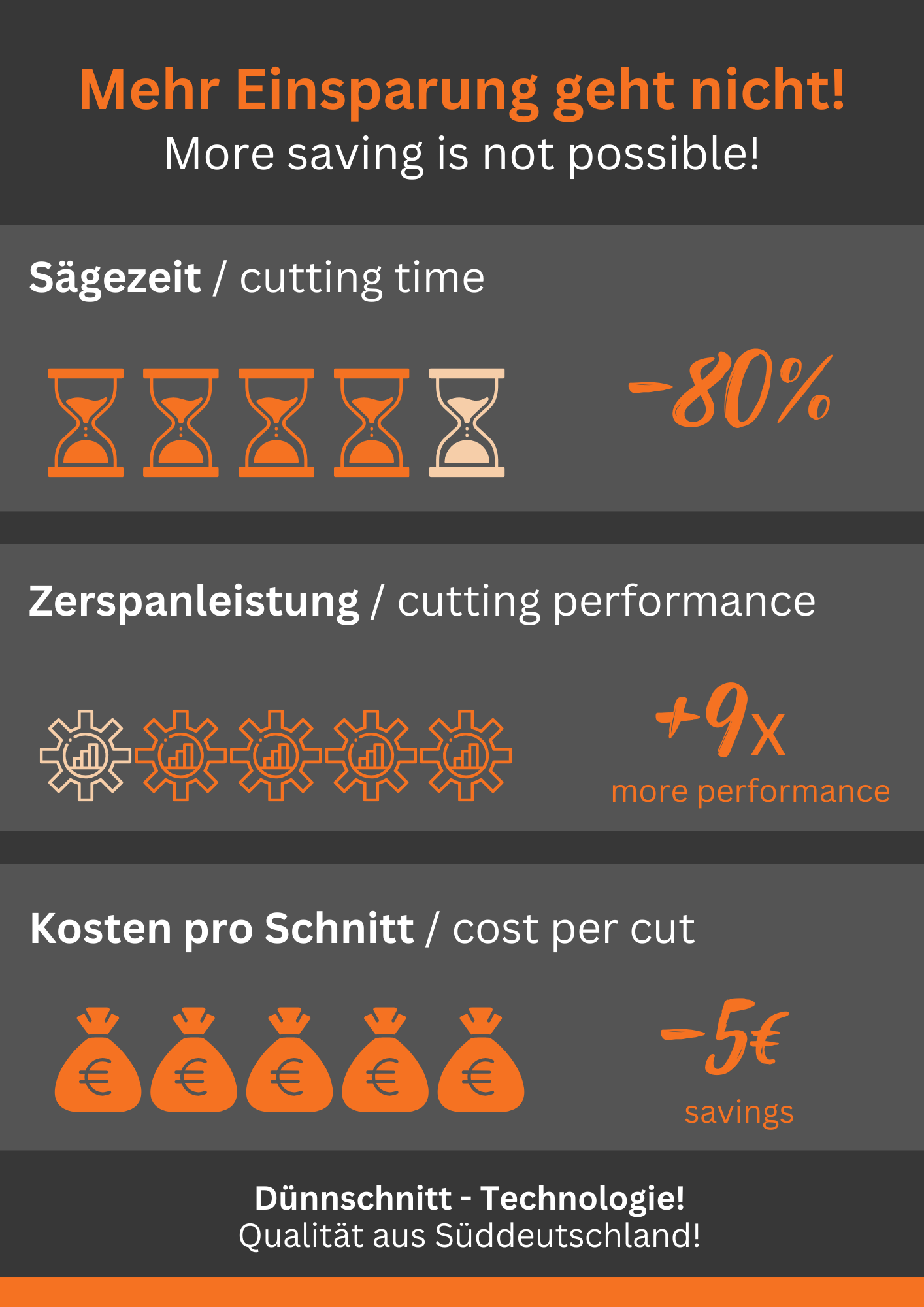

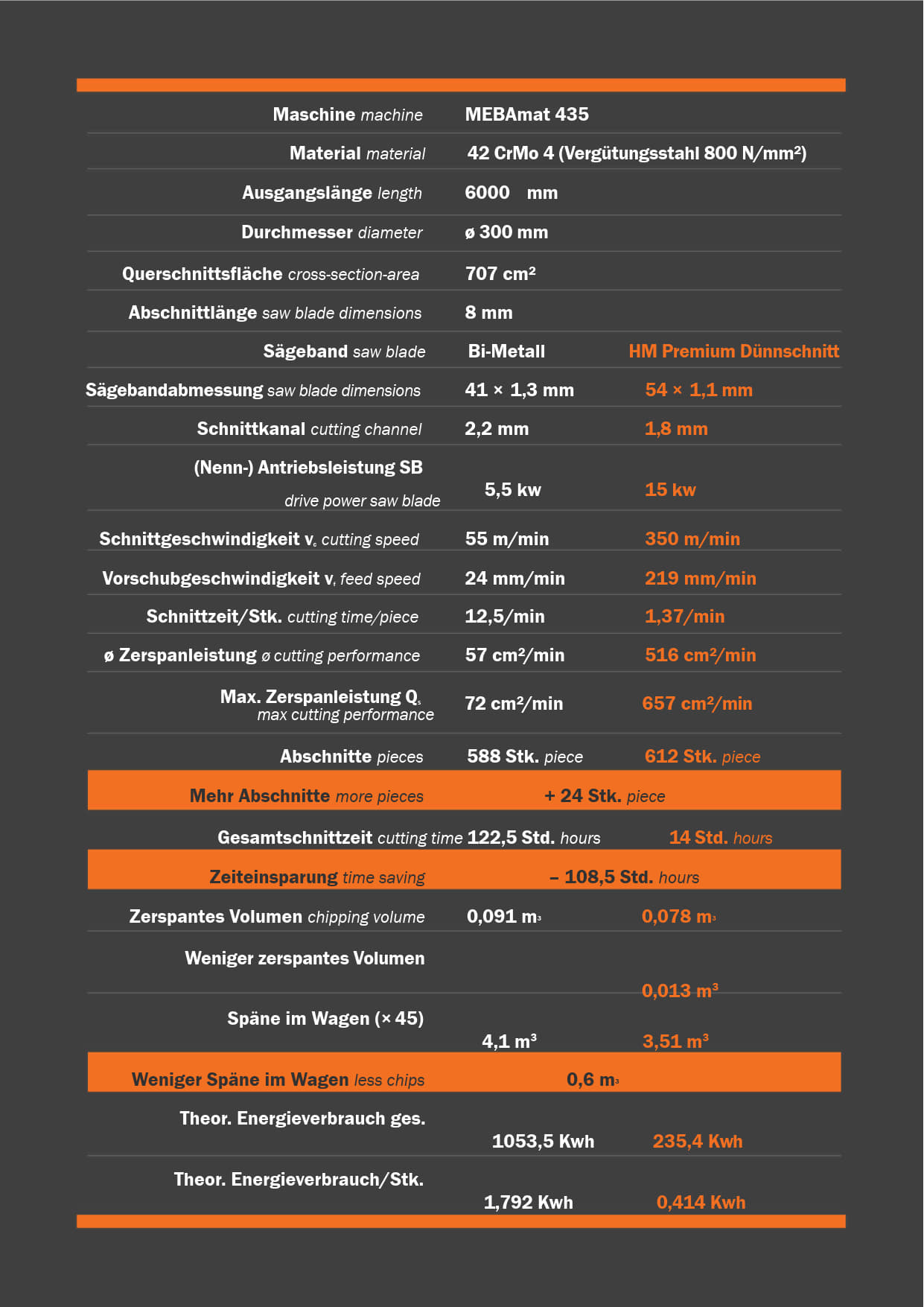

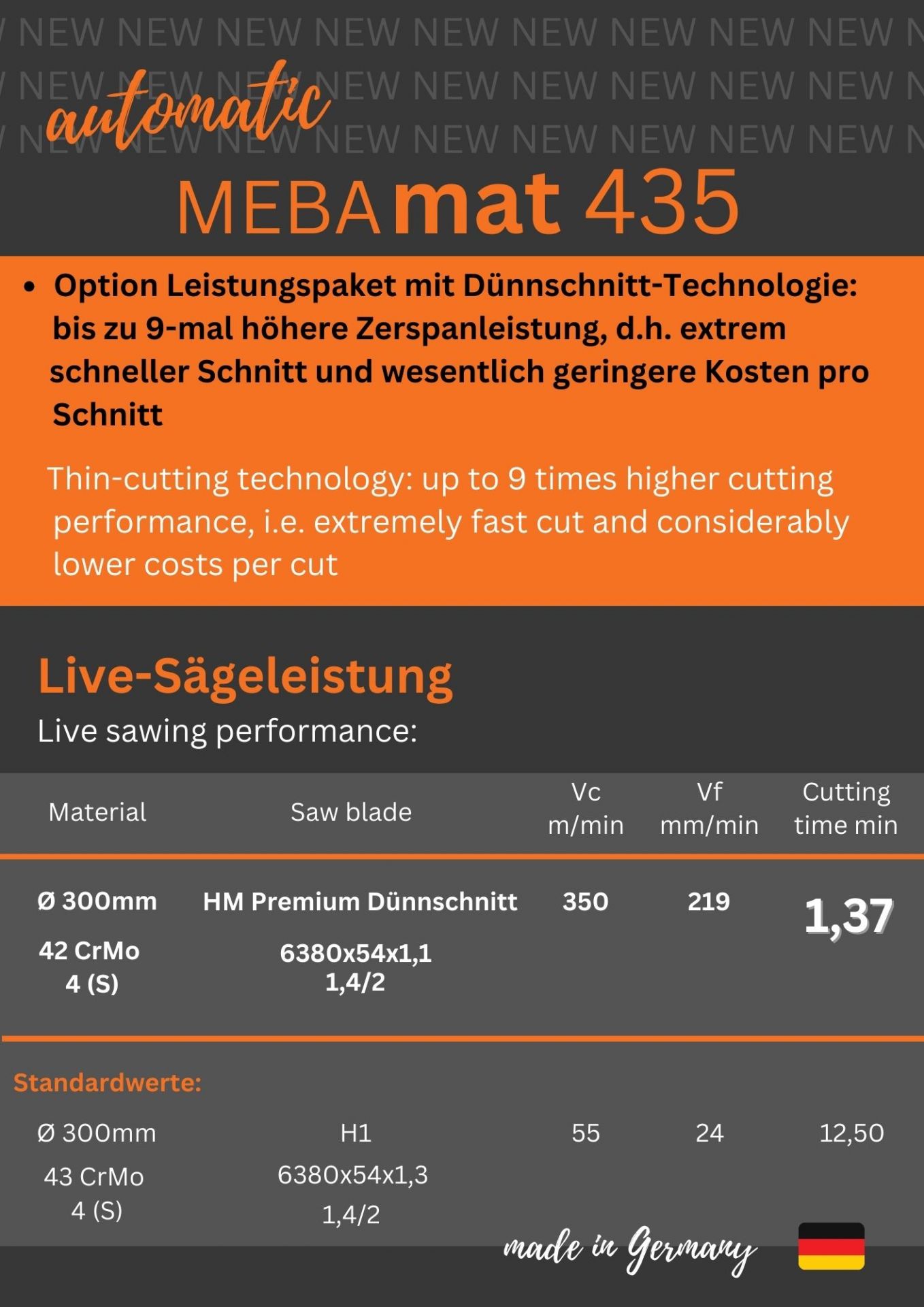

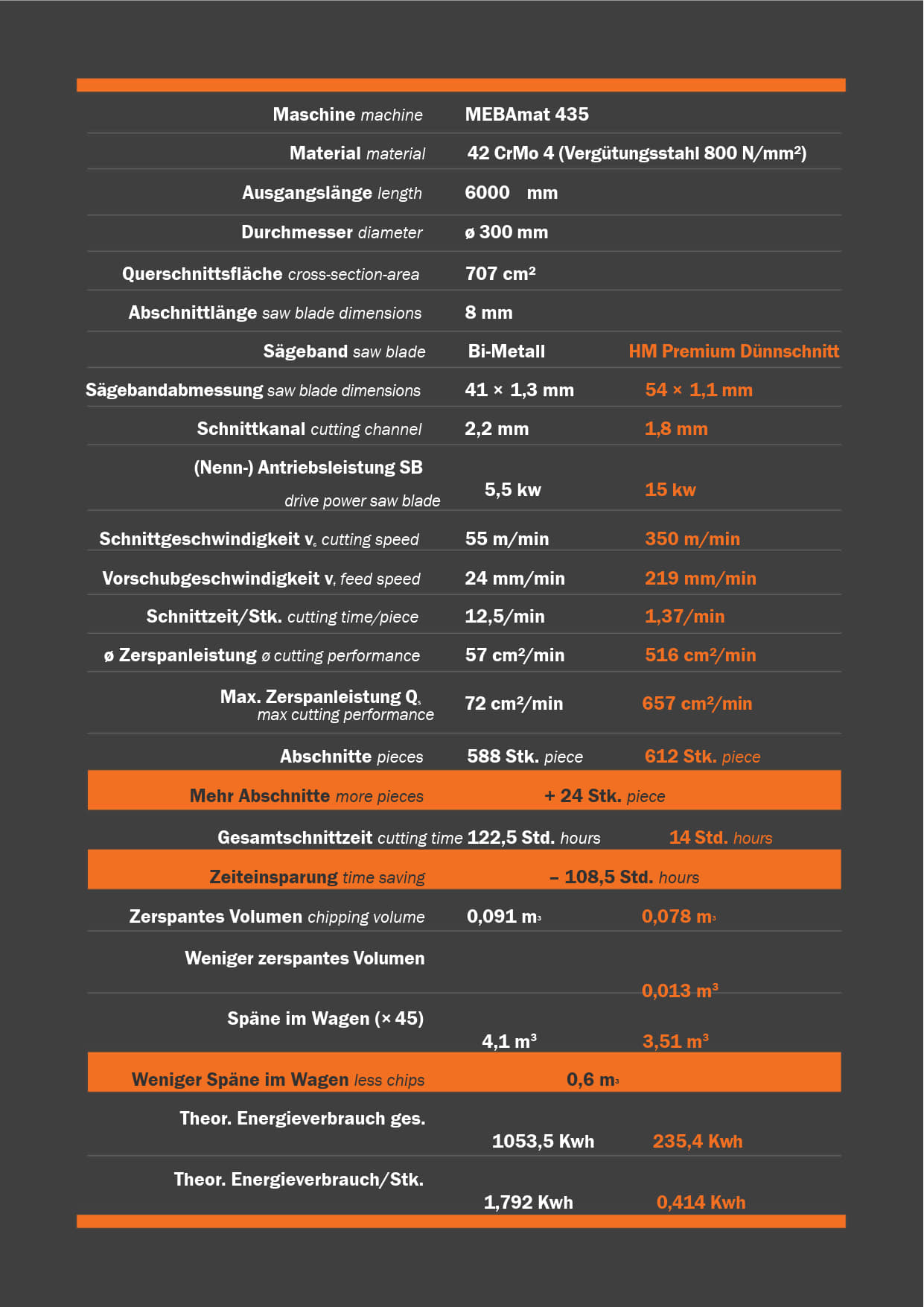

Performance package MEBAmat 435

-

Refractometer

Band tension testing device

-

Signal light with three-color status indication

-

Material lift, outfeed side

-

MEBA NC Server basic package

-

Coolant heater

-

Hydraulic unit heater

-

Control cabinet heater

- Roller conveyors available in various lengths

| Product number: | 435 MAT0000 |

|---|---|

| Automation level: | Serial cut |

| Cutting material: | Pipe, Round Stock Material |

| Cutting speed: | 15 - 150 m/min |

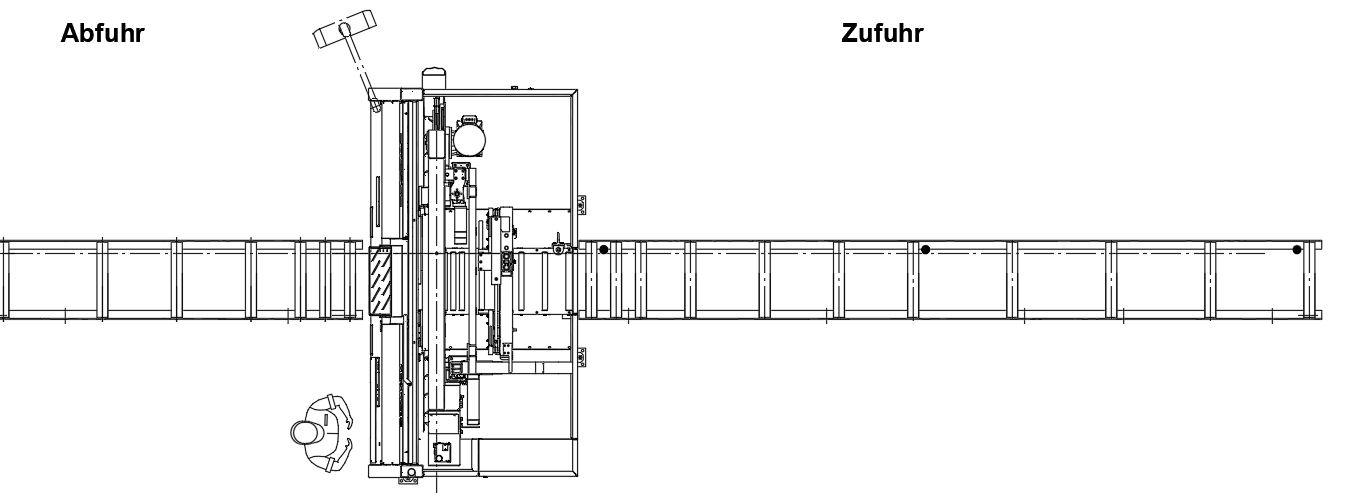

| Dimensions: | 1750x3440x2250 mm |

| Max. cutting range height ↕ (mm): | 435 |

| Max. cutting range width ↔ (mm): | 435 |

| Max. cutting range Ø (mm): | 435 |

| Remaining piece length: | 20 mm |

| Saw blade dimensions: | 6380x41x1,3 mm |

| Saw blade drive: | 5,5 kW |

| Saw blade tension: | Hydraulic |

| Type: | Miter Saw 90° |

| Type series: | MEBAmat |

| Weight: | 3500 KG |

| Working height: | 750 mm |

.png)

Login