MEBA material stand - T

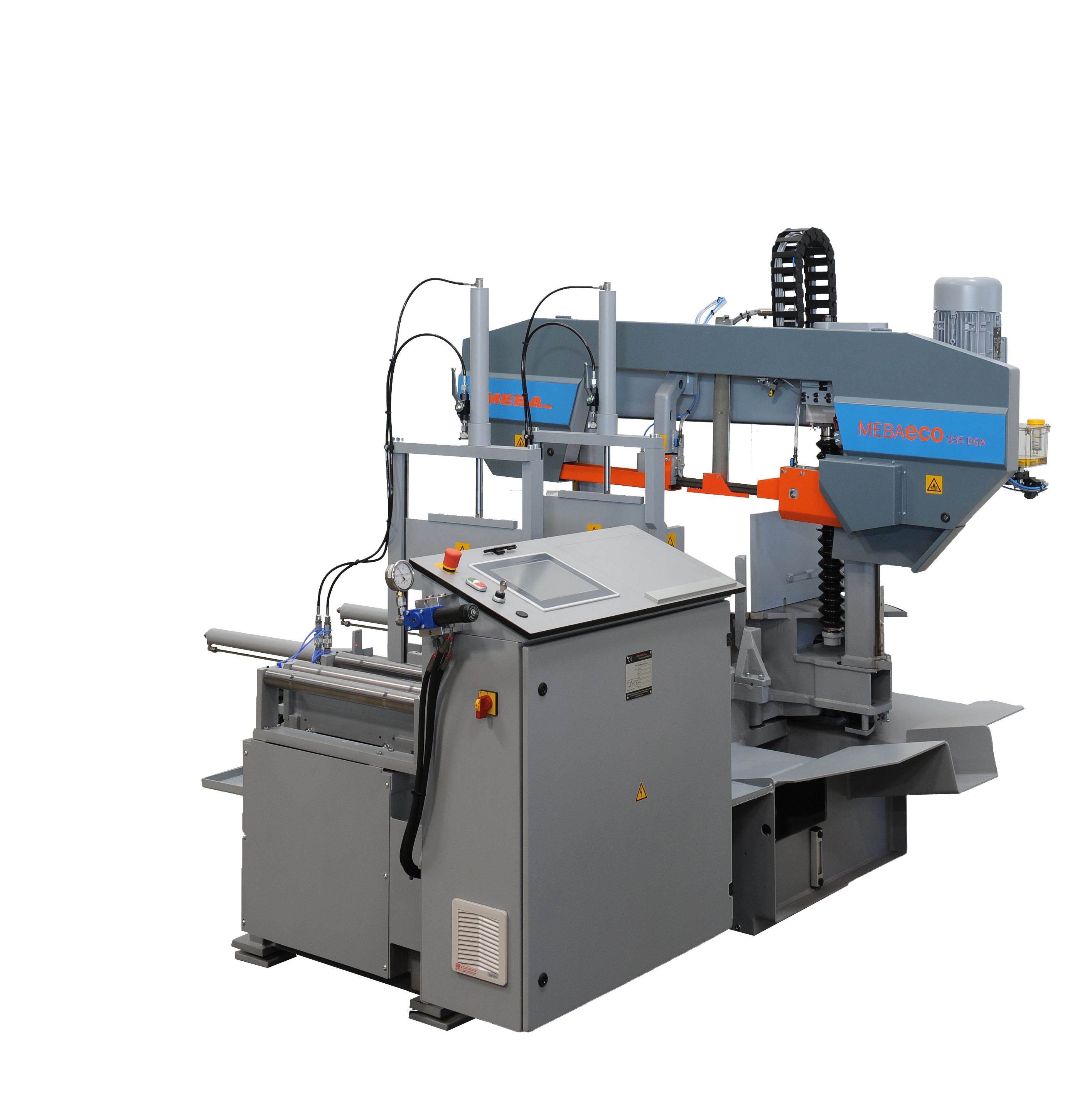

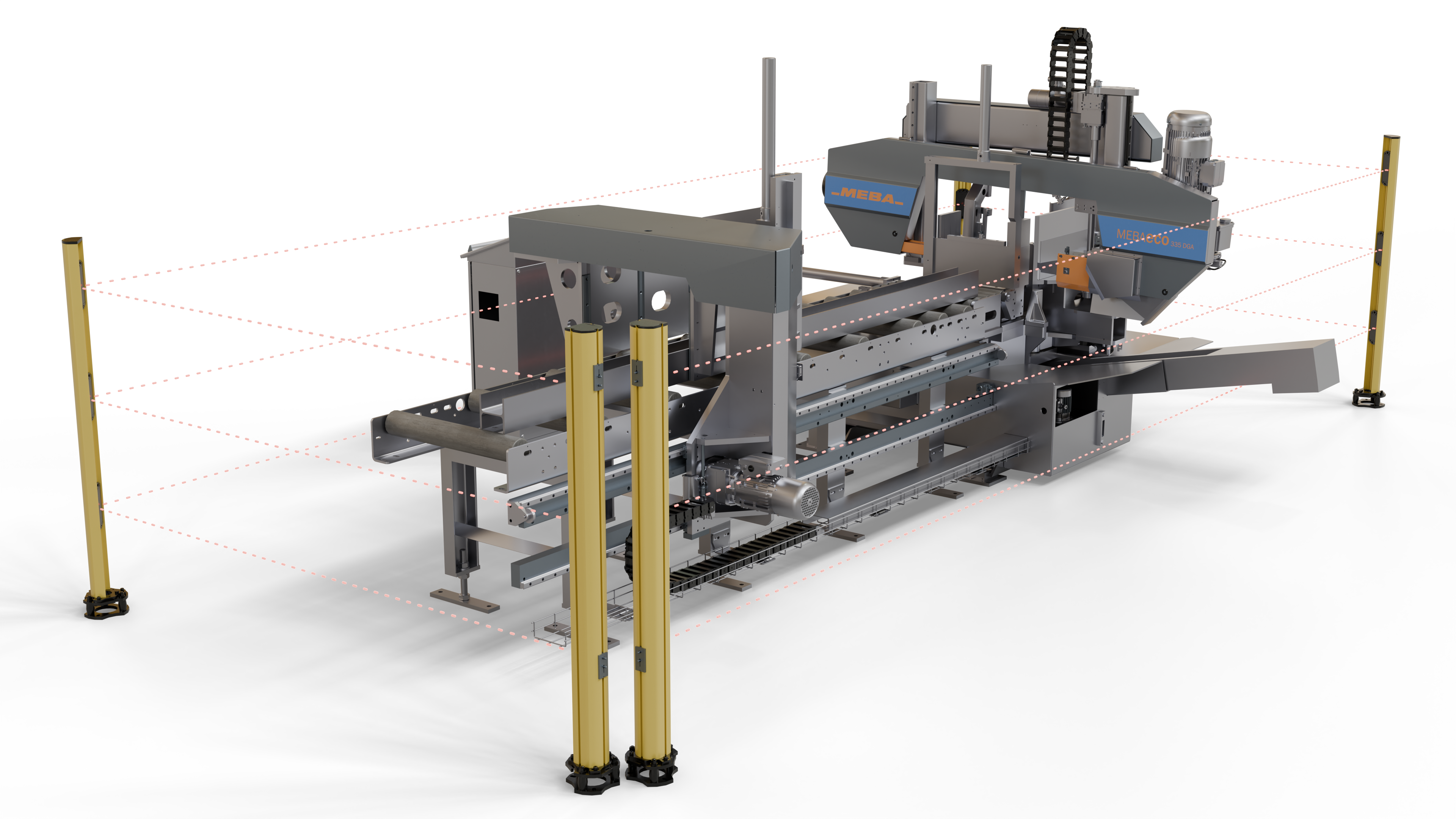

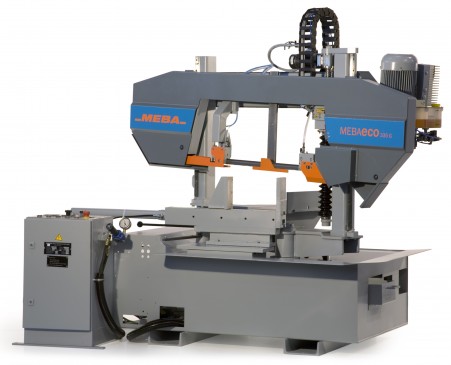

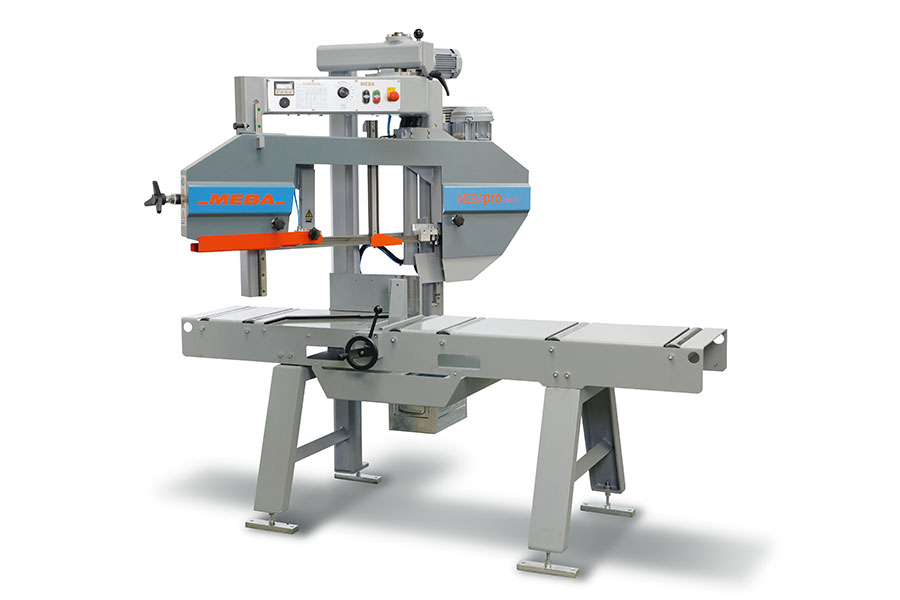

Material stand: T - design

Whether in the garage, at the craftsman's workshop or as support in the steel trade - our new material stands help you with concentrated power!

The solid construction - as well as the enormous support weight of 600 kg - means our material stands can be used in a variety of ways.

Design: TSuitable as an accessory for all machines

0 of 0 reviews

Login

Accessories

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request